Vacuum sewerage systems are ideal in areas that are subject to flooding

Nearly all vacuum sewerage systems are found in coastal area’s many of which are subject to flooding from rain/storms or rising sea levels. We all understand the problems that occur if I&I is present, we all know what causes it to occur.

Nearly all vacuum sewerage systems are found in coastal area’s many of which are subject to flooding from rain/storms or rising sea levels. We all understand the problems that occur if I&I is present, we all know what causes it to occur.

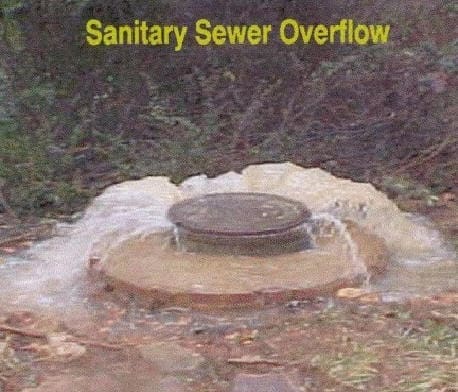

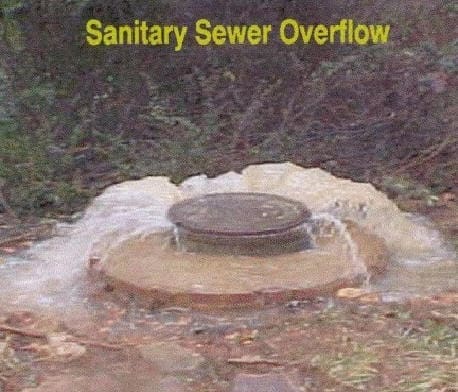

We have operated a number of systems during major floods without the system going down. In one Sydney system major floods occurred every two years (see photo above), our operations contract stated that if any homeowner could not continue to use their plumbing they would be put up at a hotel at our cost. Happily we did not spend a cent on hotel costs.

For the vacuum valve to meet the European standard it must be able to operate under a full 10 inches of water. To meet the Australian standard it must operate without problem under 18 inches of water. By ensuring all hose clips are properly in place and the controller breather is clear of any water , the system will continue to operate.

In area’s where flooding is common we tend to put the controller and controller breather in a pillar besides the pit to ensure that the operator can still fire the valve without trying to access the pit through the flood water which might not always be possible.

Water infiltration from the homeowners property.

We have found that the main source of stormwater entering a system comes from the homeowners property. In some flood areas we have seen that certain sections of the town will regularly go under water. This usually means that residents have to be evacuated and in the past the water inundation from that area could risk the whole system. In this case we would install a remotely controlled division valve that would cut off that section of the town from the vacuum system. It is controlled from the operations base so that operators are not put at risk trying to isolate the area.

In some older towns we find that some houses, or more often camping grounds or caravan parks are set at ground levels

that are blow the legislated 100 year old flood levels that people can build at. If we find houses affected in this way, they must pump into the vacuum system rather than drain into it so that the system is not put at risk.

Candycanes/Gooseneck house breather vents when placed on properties will often be a source of infiltration, usually due them either being cut down by homeowners who object to them being in the middle of their yard or by gardeners knocking them over with their lawn mowers. At times they are placed too low to the ground, under the flood level. In these cases we would install a Dedicated Pillar or think carefully about where the gooseneck vent is placed. Putting it in the middle of the yard risks it being cut down allowing water to enter the system. Putting it at the roof or garage top or against the house wall will limit water entering the system.

Smart Monitoring

As technology has improved, many asset managers have embraced the ability to locate exactly where and when I&I may be occurring. A sensor on a vacuum valve giving the open/close status will also be able to tell the operator the number of activations in a day. It is very easy for the operator to set up an alert to advise if any particular valve is operating more frequently than the general average, especially during wet weather events.

As technology has improved, many asset managers have embraced the ability to locate exactly where and when I&I may be occurring. A sensor on a vacuum valve giving the open/close status will also be able to tell the operator the number of activations in a day. It is very easy for the operator to set up an alert to advise if any particular valve is operating more frequently than the general average, especially during wet weather events.

Once the operator has established which collection pit is activating more frequently than the other valves in the area, they can then troubleshoot the problem. The likely problems are that the homeowner has cut their house vent or inspection point to allow rainwater to enter the system or may have connected up their stormwater system to the sewer system or have a cracked gravity line feeding from the house to the pit. A letter to the homeowner to make the necessary rectifications is required.

There may also be groundwater or stormwater entering the collection pit due to incorrect pipework entering the pit allowing for water to enter. This is usually picked up at commissioning, if not should now be rectified.

You should also make sure that the pit lid is made for area’s that have flooding and has a seal and no holes to allow water to enter. the pit should not be located at a low point in the street.

The monitoring system makes it possible to identify these problems and fix them. this is not possible in a gravity system.

System Design

When designing a gravity sewer consideration must be made for Infiltration and Inflow on the pipes, the pump stations and the treatment plant.

When designing a gravity sewer consideration must be made for Infiltration and Inflow on the pipes, the pump stations and the treatment plant.

Stormwater cannot enter the vacuum system via the vacuum pipework as it must remain tight for the vacuum pressure to hold tight. If a break occurs in a main it is immediately noticed and repaired.

An allowance is made for I&I but only for a small amount of the network, that being the homeowner gravity lines. So the system is not designed for infiltration and all steps must be taken to ensure that it does not occur. Luckily in a vacuum system the source of any I&I can be located.

If you have any leaks into your system, contact an expert for advice.

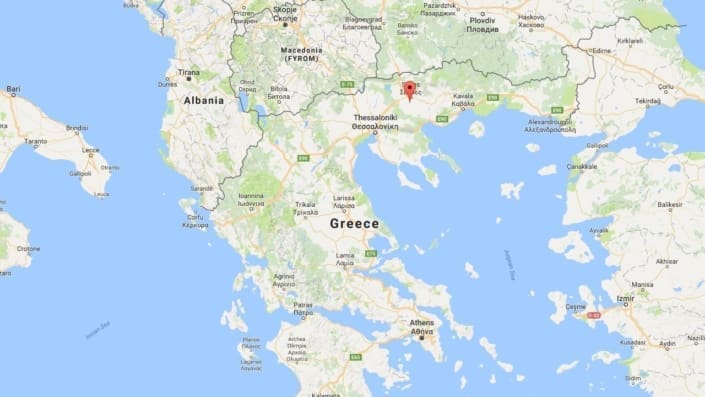

Flovac Greece has just completed the largest vacuum sewerage system ever undertaken in Greece covering the towns of Mitrousi and Skoutari in the Serres Region of northern Greece.

Flovac Greece has just completed the largest vacuum sewerage system ever undertaken in Greece covering the towns of Mitrousi and Skoutari in the Serres Region of northern Greece. The Serres region is an environmentally important area which won a European sustainable tourism award for aquatourism. A large artificial lake, Lake Kerkini was created nearby to make use of the extensive marshlands in the area. This is also behind the need for vacuum sewers in the villages as the water table is very high and actually visible on the surface in some areas.

The Serres region is an environmentally important area which won a European sustainable tourism award for aquatourism. A large artificial lake, Lake Kerkini was created nearby to make use of the extensive marshlands in the area. This is also behind the need for vacuum sewers in the villages as the water table is very high and actually visible on the surface in some areas.

Nearly all vacuum sewerage systems are found in coastal area’s many of which are subject to flooding from rain/storms or rising sea levels. We all understand the problems that occur if I&I is present, we all know what causes it to occur.

Nearly all vacuum sewerage systems are found in coastal area’s many of which are subject to flooding from rain/storms or rising sea levels. We all understand the problems that occur if I&I is present, we all know what causes it to occur.

As technology has improved, many asset managers have embraced the ability to locate exactly where and when I&I may be occurring. A sensor on a vacuum valve giving the open/close status will also be able to tell the operator the number of activations in a day. It is very easy for the operator to set up an alert to advise if any particular valve is operating more frequently than the general average, especially during wet weather events.

As technology has improved, many asset managers have embraced the ability to locate exactly where and when I&I may be occurring. A sensor on a vacuum valve giving the open/close status will also be able to tell the operator the number of activations in a day. It is very easy for the operator to set up an alert to advise if any particular valve is operating more frequently than the general average, especially during wet weather events. When designing a gravity sewer consideration must be made for Infiltration and Inflow on the pipes, the pump stations and the treatment plant.

When designing a gravity sewer consideration must be made for Infiltration and Inflow on the pipes, the pump stations and the treatment plant.

This historic village nestled on the banks of the Loire River near the French city of Nantes on the Atlantic coast of France is the site of the latest Flovac system in Europe.

This historic village nestled on the banks of the Loire River near the French city of Nantes on the Atlantic coast of France is the site of the latest Flovac system in Europe. The town is in the heart of an important agricultural area and has very flat and sandy soil, ideal for a vacuum system. It is also known as the town that first developed the beurre blanc sauce, often used in french cuisine. There are also vines on the hills around the town that grow a muscadet wine that is very popular.

The town is in the heart of an important agricultural area and has very flat and sandy soil, ideal for a vacuum system. It is also known as the town that first developed the beurre blanc sauce, often used in french cuisine. There are also vines on the hills around the town that grow a muscadet wine that is very popular. The system is able to be installed with only a single vacuum pump station which is also important in an old town like Saint Julien in that space is a precious commodity. It was also important to keep energy use as low as possible, and with a single small vacuum pump station, this is possible.

The system is able to be installed with only a single vacuum pump station which is also important in an old town like Saint Julien in that space is a precious commodity. It was also important to keep energy use as low as possible, and with a single small vacuum pump station, this is possible.

Although vacuum systems are newcomers to the sewerage industry we are seeing some systems just reaching their 50th anniversaries. Materials and designs have changed significantly since the first systems were installed in the mid sixties and although many are still operating they are nearing the end of their design life of the time.

Although vacuum systems are newcomers to the sewerage industry we are seeing some systems just reaching their 50th anniversaries. Materials and designs have changed significantly since the first systems were installed in the mid sixties and although many are still operating they are nearing the end of their design life of the time. When looking at whole of life costs the primary maintenance item in the vacuum pump station are the vacuum pumps. Liquid ring pumps have lower ongoing costs but use a lot of water which can be expensive. Rotary vane Pumps require oil changes and filter changes and rebuilds are more common.

When looking at whole of life costs the primary maintenance item in the vacuum pump station are the vacuum pumps. Liquid ring pumps have lower ongoing costs but use a lot of water which can be expensive. Rotary vane Pumps require oil changes and filter changes and rebuilds are more common.