Miles Crossing Oregon

Not long after Miles Crossing Sanitary Sewer District in Oregon installed a new vacuum sewer system they realized they had an issue that needed an immediate fix. According to the superintendent, Carl Gifford, “Our flows exceed 180,000 gallons [on heavy rain days] due to a massive I/I issue that we grew to have”. This excess can put a strain on the system which can increase utility bills, not to mention, Miles Crossing is a collection system only. They have to work with a neighboring system for treatment and have a limit on max flow that can be sent.

Not long after Miles Crossing Sanitary Sewer District in Oregon installed a new vacuum sewer system they realized they had an issue that needed an immediate fix. According to the superintendent, Carl Gifford, “Our flows exceed 180,000 gallons [on heavy rain days] due to a massive I/I issue that we grew to have”. This excess can put a strain on the system which can increase utility bills, not to mention, Miles Crossing is a collection system only. They have to work with a neighboring system for treatment and have a limit on max flow that can be sent.

Flovac and Miles Crossing were able to meet and come up with a plan to utilize Flovac Monitoring System to overcome these issues.

“With this system, we can monitor the fires from each individual pit. During a rain event, it is really simple to tell which ones contribute to the massive I/I we are dealing with. During the last winter, we were able to identify 9 sources of I/I that we were able to repair”.

Gifford also mentions how the system allows for the sewer district to know about problems before customers do. “An additional benefit that we observed with this system is the alarms that it provided. Numerous times we were called out for a high-level at a residence and were able to make the repair and get it back online before the customer knew there was a problem. This helps greatly with the risk management of possible failures and the following lawsuits that have happened in the past”.

Due to less load on the system, Miles Crossing have been able to add residential connections creating revenue.

To find out more about the Flovac Monitoring System – Click Here

Image on Front Cover Torsten Blackwood—AFP/Getty Images

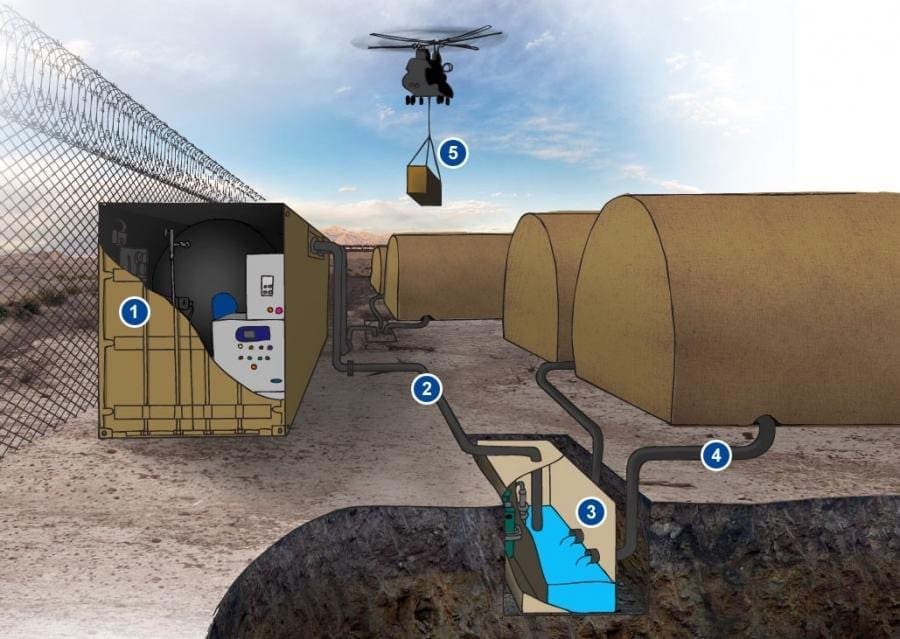

Vacuum sewerage systems almost always cost less to install and less to maintain than traditional gravity systems, and certainly less than pressurized systems with grinder pumps. A single vacuum pump station will usually be sufficient to support an entire project.

Vacuum sewerage systems almost always cost less to install and less to maintain than traditional gravity systems, and certainly less than pressurized systems with grinder pumps. A single vacuum pump station will usually be sufficient to support an entire project. Overcome Site Conditions

Overcome Site Conditions

Wastewater and Bilge Water

Wastewater and Bilge Water

Flovac was asked to design and supply a vacuum system that would be able to handle the high flows that will ultimately be handled by the Resort. The vacuum system needed to facilitate not only the hotel but also residential areas, restaurants and the marina. The client was aware of the good work which Flovac had done at Reef Island in Bahrain and was particularly impressed with the monitoring system that had been installed. The monitoring allows operators to see exactly what was happening anywhere in the network including the operation of the vacuum pump station. Mr Willem Gooren one of the founders of Flovac managed the project and was based in the Middle East for extensive periods during the projects establishment and finalization.

Flovac was asked to design and supply a vacuum system that would be able to handle the high flows that will ultimately be handled by the Resort. The vacuum system needed to facilitate not only the hotel but also residential areas, restaurants and the marina. The client was aware of the good work which Flovac had done at Reef Island in Bahrain and was particularly impressed with the monitoring system that had been installed. The monitoring allows operators to see exactly what was happening anywhere in the network including the operation of the vacuum pump station. Mr Willem Gooren one of the founders of Flovac managed the project and was based in the Middle East for extensive periods during the projects establishment and finalization.