Resiliance in Action: How Vacuum Sewers Protected a Flooded Town

How Vacuum Sewer Systems Helped Thargomindah Survive Australia’s Record Flood

In April 2025, the remote outback town of Thargomindah, Queensland was struck by the worst flooding in its history. Entire paddocks turned into inland seas. Emergency shelters filled. And yet, despite the odds, the town’s vacuum sewerage system held its ground — quite literally — thanks to smart planning, fast logistics, and the heroic commitment of one family and their monitoring system.

The Flood That Changed Everything

Thargomindah Flooding

The Bulloo River spilled over in March and April, inundating homes, council infrastructure, and even the camping ground where many residents sought temporary shelter. Despite this, toilets kept flushing, and ablution blocks stayed online — a quiet miracle powered by vacuum technology and dedication on the ground.

To add perspective. The flooded area was the size of Vistoia or three times the size of The Netherlands

What the Council Did Right (Before the Rain)

Jacinta Byrne Hometown Hero

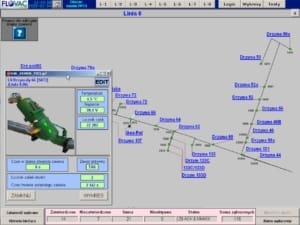

The Bulloo Shire Council, together with Flovac, had already begun preparations the year before. Actions taken included:

• Raising controller pillars above flood levels.

• Stocking spares in advance and securing supply lines.

• Using real-time monitoring to identify problems before they escalated.

Even though floodwaters exceeded predicted levels and entered pits and controller enclosures, the raised design made recovery and cleaning easier.

Cleaning Up still had to take place

When Monitoring Saves the Day

Between March 25–29, vacuum pressures in the system plummeted and valve activations surged to over 800 per day, causing alarms to light up across the system. But this wasn’t failure—it was stress detection.

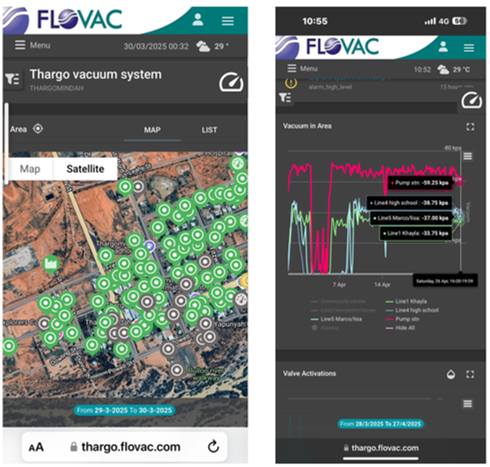

Flovac’s wireless monitoring allowed local technician Daryl Byrne to track the situation in real time, identify failing pits, and respond before services broke down.

Wireless Monitoring System

Even in such a remote location the wireless system could still function

The Byrne Family: Unsung Heroes of the Outback

With Daryl’s help, Jacinta and Dalton Byrne were out in the field daily—and nightly. According to Daryl:

The Byrne family, jacinta and Dalton On call 24 hours

“There were some late nights and early mornings when Jacinta would come and grab Dalton at 3 a.m., saying we’ve got a red light. They’d both head out and by morning have all green lights, just in time for everyone needing the toilets.”

They manually cycled pump stations to ensure flow from flooded ablution blocks, restored failed pits, and cleaned and tested each unit before handing them back to Council.

Why Vacuum Systems Are Built for Resilience

- Are sealed and airtight, preventing stormwater infiltration into the vacuum network.

- Areas where infiltration was occurring from homes was easily identifiable.

- Allow for elevated control installations.

- Operate with centralised pump control, avoiding multiple flooded pump stations.

- Can be remotely monitored and manually overridden during emergencies.

Flovac Support in the Background

Even during regional isolation, Flovac delivered new parts to Thargomindah in days. Their stock network and manufacturing readiness meant that vital equipment was replaced quickly, preventing service interruptions.

Lessons for Other Councils

1. Elevate infrastructure where you can.

2. Monitor and maintain in real time.

3. Train local champions—they make or break emergency response.

4. Choose vacuum when terrain and weather challenge gravity systems.

________________________________________

Closing

In the end, this wasn’t just a test of pipes and valves—it was a test of people and planning. Thargomindah passed.

Proud dad Daryl with Jacinta. Dalton out helping, not in picture. he said he was too busy working.

monitoring technology is to provide the district with real-time alerts of system issues as a means of mitigating SSOs. The installation is expected to take approximately two years to complete and will utilize a basin-by-basin approach to make such a large-scale project manageable. The monitoring technology will be deployed throughout the district’s vacuum collection system, grinder pump collection systems and force mains. This includes nearly 3,000 collection pits.

monitoring technology is to provide the district with real-time alerts of system issues as a means of mitigating SSOs. The installation is expected to take approximately two years to complete and will utilize a basin-by-basin approach to make such a large-scale project manageable. The monitoring technology will be deployed throughout the district’s vacuum collection system, grinder pump collection systems and force mains. This includes nearly 3,000 collection pits.