1,000,000 cycles. How long should your vacuum valve last.

A vacuum interface valve is located in a collection pit usually outside of the property boundary at the side of the road. In most systems this collection pit is connected to 4 to 6 homes via a gravity pipe connection.

Although the vacuum system is designed so that the vacuum valve allows for a flow of .25 litres per second (4 gallons per minute) from the houses. There are some occasions where parts of a system may be designed for higher flows. This may come from schools, commercial areas, gravity fed or pumped flows. Our engineers are very careful about how these higher flows enter the system.

Although the vacuum system is designed so that the vacuum valve allows for a flow of .25 litres per second (4 gallons per minute) from the houses. There are some occasions where parts of a system may be designed for higher flows. This may come from schools, commercial areas, gravity fed or pumped flows. Our engineers are very careful about how these higher flows enter the system.

The vacuum valve is designed to activate pneumatically once 40 litres (10 gallons) enters the collection pit. This allows for a mix of air and water to enter the system with the correct air to liquid ratio so that the vacuum mains do not flood with too much liquid. In an average residential community, the vacuum valve will activate between 80 and 100 times per day. This is based on the average flow per house and the number of houses per collection pit.

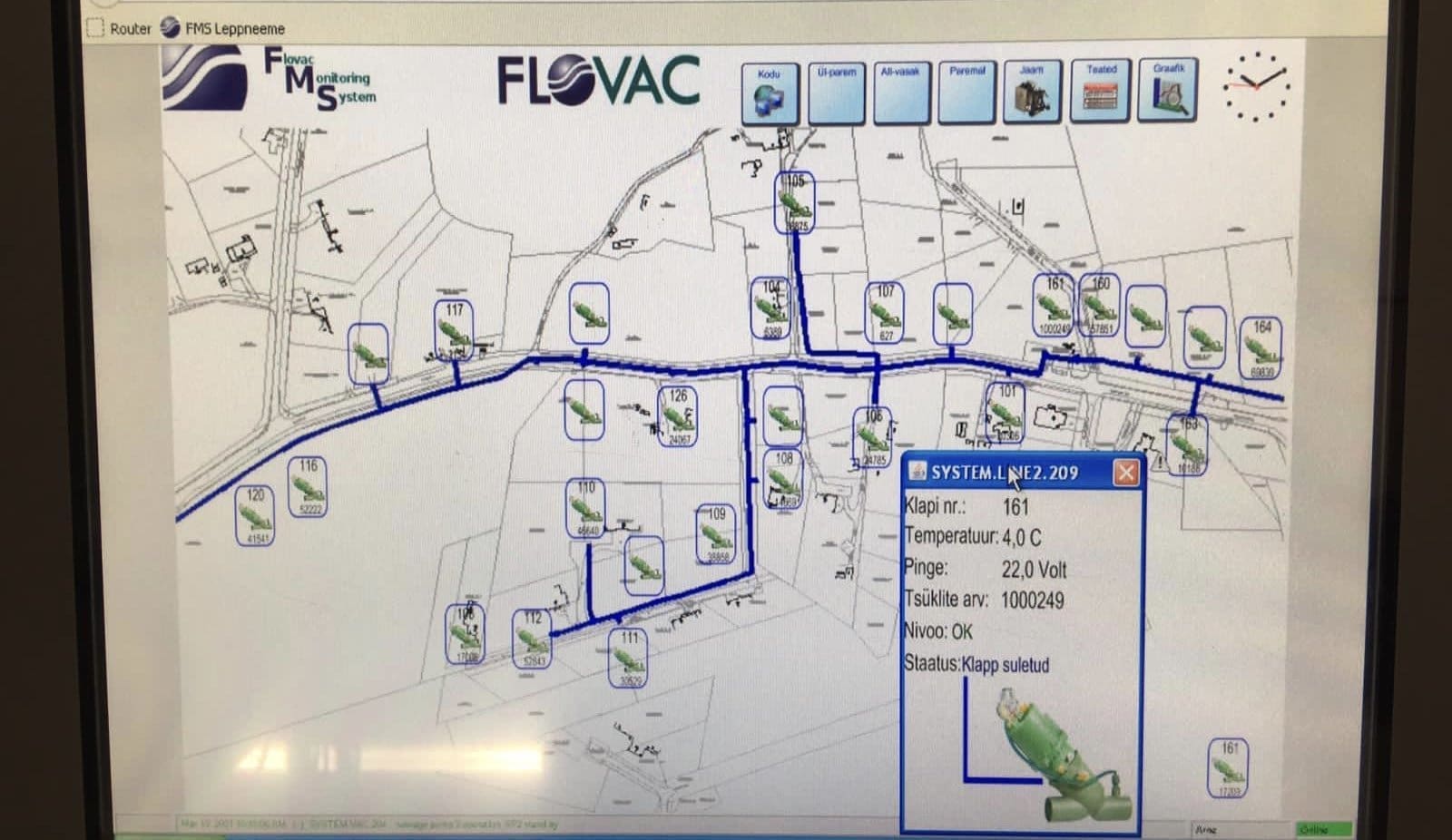

Flovac Manager Georg Sarap checking the monitoring system via the touch screen at the vacuum pump station

For maintenance we recommend that certain parts in the valve and controller are replaced every 10 years or 300,000 cycles. The body itself has a design life of 50 years. European Standard EN 16932 calls for an endurance test with 250,000 cycles, as does the Australian Standard AS 4310 Details Here

Flovac has independant testing of the valve at 700,000 cycles, significantly more than required by the standards and represents 23 years of activation without failure.

We know that in a number of our systems we have some very high flow situations. With some its been due initially to infiltration which clients have since resolved. With others the system has been designed to cater for very high flows. High Flow Projects .

One Million Cycles

Monitoring screen showing over 1 million cycles

At our project at Leppneeme in Estonia our team has been watching one of our high flow valves closely. It has a Flovac cable monitoring system which can tell the operator the number of times the valve has operated (Tsuklite arv:). It can also alert the operator to any faults, tell the temperature in the pit, the power use and location. The pit is located very close to the vacuum station which makes it easier to handle very high flows. This week the valve passed its 1 million mark with number of cycles. Based on these activations it has done 34 years worth of work in just 8 years and is still going strong.

Fortunately the operator would be able to tell from the monitoring system if any parts were wearing as the open time of the valve would start to change.

Although we have other systems that have valves which have recorded over 1 million cycles as well as achieving this result on our test bench it has been great watching it tick over via our monitoring system.

The challenges: we had the right product at the time when pollution, the environment and water saving were serious issues. Canal developments were popular. There were backlogs of projects to replace odorous septic tanks with vacuum. W.A. had $800 million put aside to fix their sewage deficiencies. Wastewater experts were reassessing the benefits of the technology moving into the digital age as installation damage was minimal, with flexibility to go around, under or over obstacles and easy maintenance were winners. An industry of people who did care.

The challenges: we had the right product at the time when pollution, the environment and water saving were serious issues. Canal developments were popular. There were backlogs of projects to replace odorous septic tanks with vacuum. W.A. had $800 million put aside to fix their sewage deficiencies. Wastewater experts were reassessing the benefits of the technology moving into the digital age as installation damage was minimal, with flexibility to go around, under or over obstacles and easy maintenance were winners. An industry of people who did care.