Operational Costs for Vacuum Sewer Systems

How much does it cost to operate and maintain your vacuum sewer system? Is that high and what is normal? Lets also talk about the best way to reduce your maintenance costs.

Critical Factors

Flovac’s operations group has completed audits of systems in many locations and through our benchmarking process we have determined a number of common factors involved.

Before we dig deeper there are two important statements we can make.

- You need to know how much your vacuum systems costs to operate. Most utilities, do not know. Once you understand what the main costs are, you can do something about them

- All systems which have monitoring systems installed have significantly lower operational costs as well as reduced risks.

The overall cost varies, smaller versus larger, country to country, so its probably best to focus on what makes up the cost. Try and find what was in the whole of life costs when this system was first being suggested. How accurate was that. If it is different, why is it different and if more expensive, what can be done about it.

Vacuum systems should always be cheaper to operate than a low pressure pump system and in a similar difficult location should have cheaper operations costs than a gravity system with multiple pump stations.

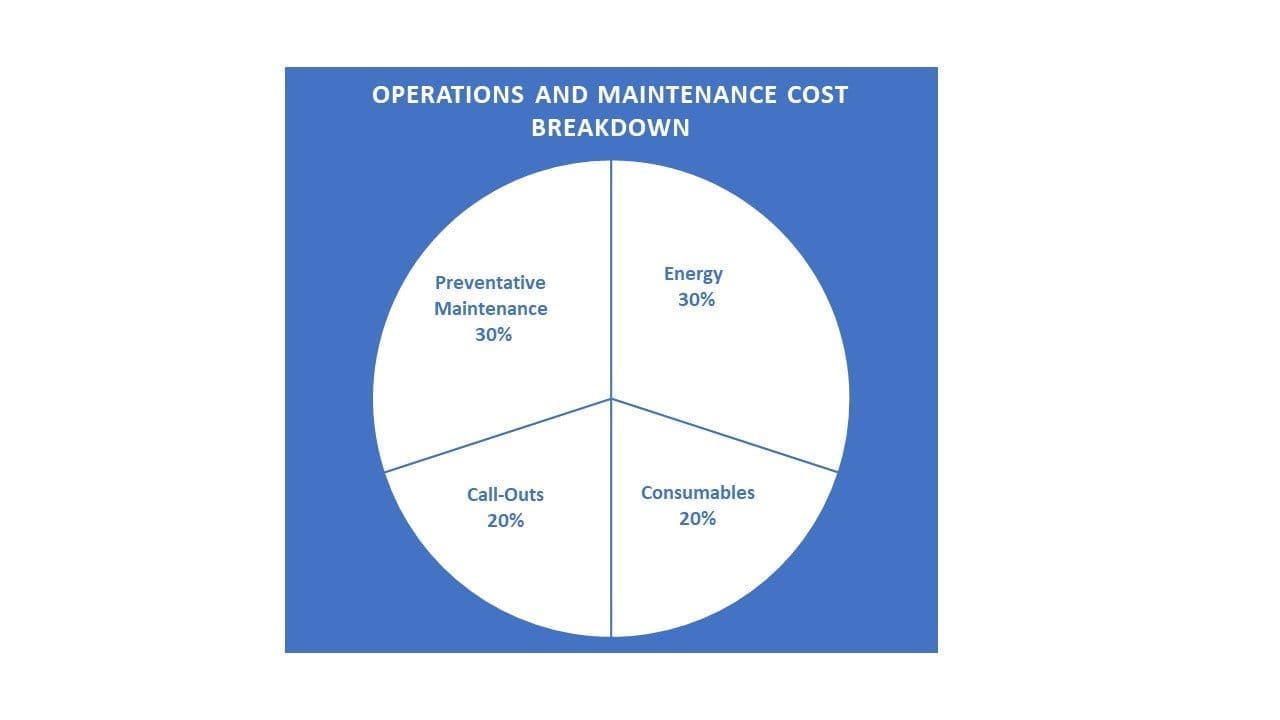

Cost Breakdown

- Energy Costs (30{f2ac4d1e1d40dc2e2d9280a1dfa90d854b2d8c80eba743affa37fc4ce2e16def}). For many utilities this is one of the easiest things to focus on and also easiest to get accurate data on. It could be that your pumps are just old and it’s time for a rebuild/service or replacement. With vacuum systems, energy costs are highly correlated with the air/liquid ratio of the system. That’s our first design principal and our first operational health check. Air transports the sewage to the station. The amount of air is measured by the vacuum pump run times and the size of the pumps. If there is too much air, either due to leaks in the system, old valves or badly tuned valves then your vacuum pumps will run longer than needed. In most systems vacuum pumps should run approximately 6 hours per day. Sewage pump run times are determined by the amount of sewage in the system. If you have infiltration or a user dumping in more than they should, then your pump run time will increase. In most vacuum systems the sewage pumps should run about 2-3 hours per day. You need to check what the optimal air to liquid ratio is for your system. When it is at its optimal level your energy costs should be at their lowest possible point.

- Consumables (20{f2ac4d1e1d40dc2e2d9280a1dfa90d854b2d8c80eba743affa37fc4ce2e16def}) In vacuum systems consumables can either be related to parts for the vacuum valves and controllers, or related to pump station equipment. This is different to long term capital replacements, pump and valve replacements, this is covering annual spending on oil and filters and valve/controller parts. In our experience of sales of parts to systems, valve and controller parts should only be required every ten years. It is highly unusual for sales to be any more frequent than this. In most pump stations the main cost is oil and filters for rotary vane vacuum pumps. Liquid ring pumps and claw vacuum pumps require a lot less maintenance but might not handle the required duty for your system. The best way to reduce your oil costs is to reduce the run time on your pumps. See the above section on energy costs. If you are watching the air/liquid ratio and keeping your pump run times at optimal levels then your oil requirements will be minimal.

- Preventative Maintenance (30{f2ac4d1e1d40dc2e2d9280a1dfa90d854b2d8c80eba743affa37fc4ce2e16def}) A number of systems do no preventative maintenance at all and so this 30{f2ac4d1e1d40dc2e2d9280a1dfa90d854b2d8c80eba743affa37fc4ce2e16def} cost will be lumped in with call-outs. We would tend to visit each pit once a year to check the pit condition, valve condition and controller timing. At every ten years we replace the required parts in the valve and controller. With monitoring a lot of our preventative maintenance time is spent at the computer. Analysing data to show infiltration, air/liquid ratio, changes to end of line pressure, failing components and remotely adjusting the timing of certain controllers to take into account seasonal flows as required.

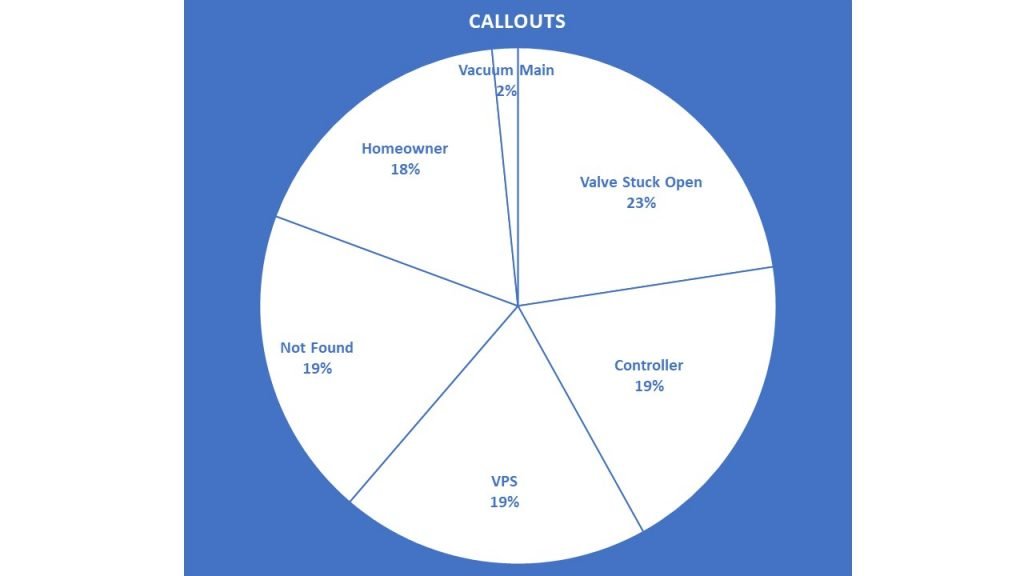

- Call-Outs (20{f2ac4d1e1d40dc2e2d9280a1dfa90d854b2d8c80eba743affa37fc4ce2e16def}) If preventative maintenance is done correctly then this number should remain low. We have outline in the following graph the breakdown of callouts to a vacuum system. A system with 200 vacuum valves should have a 5{f2ac4d1e1d40dc2e2d9280a1dfa90d854b2d8c80eba743affa37fc4ce2e16def} call-out rate, meaning that there should be 10 callouts in the year. The biggest cost here is time spent in the field finding the fault. In many projects we have found that a refresher training program for the operators can help reduce time in the field a lot. The other biggest cost reduction comes from installing a monitoring system. Have the operator being directed directly to a problem or being told ahead of time when a controller is going to fail can save significant money and resources.

Follow Up

If you would like to follow up on any of these points please contact your closest Flovac office. You can contact our Operations group about audits or training courses, or just some advice about your system. If you would like to see some more information about monitoring systems you can Click Here