Gravity sewers have been used for hundreds of years, but they come at a much higher cost than many options reports accurately record. When selecting what type of sewerage system to use, take into account the risks associated with the solution. What happens if a sewer overflows? What happens if a storm or large wet weather event occurs. What will happen if a pipe breaks. What will be the cost and what will be the risk? A vacuum sewer could be far cheaper than you realise.

Gravity sewers have been used for hundreds of years, but they come at a much higher cost than many options reports accurately record. When selecting what type of sewerage system to use, take into account the risks associated with the solution. What happens if a sewer overflows? What happens if a storm or large wet weather event occurs. What will happen if a pipe breaks. What will be the cost and what will be the risk? A vacuum sewer could be far cheaper than you realise.

When you reflect on the damage and the cost of exfiltration from sewer networks the statement that we often hear ‘gravity sewers require no maintenance – we just put them in and leave them be” is wrong and does not reflect the true risks of not only gravity systems, but also low pressure systems as well as old septic tanks and combined sewers.

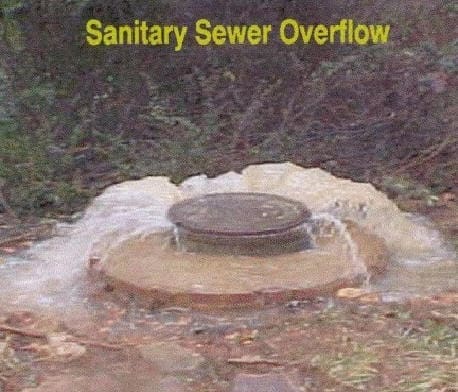

Sewage leaks can occur for a number of reasons. the most common is leaking sewer pipes (this may be caused by tree roots or ground movement). A break in a gravity line can remain undetected for months or even years. In a Low Pressure Pump system a break will lead to a surcharging sewer which will be difficult to repair and costly.

Sewage leaks can occur for a number of reasons. the most common is leaking sewer pipes (this may be caused by tree roots or ground movement). A break in a gravity line can remain undetected for months or even years. In a Low Pressure Pump system a break will lead to a surcharging sewer which will be difficult to repair and costly.

With Low pressure systems a pipe break is easier to detect as some local TV news anchor is excitedly showing the 50 foot geyser in the middle of main street.

Overflows can also be caused by the system being inundated with stormwater which overwhelms the entire system allowing polluted stormwater to enter waterways.

A vacuum sewer piping network is leak tight, as it operates under a negative pressure any break cannot allow exfiltration to occur and as the pipe is less than 1/3 full at any time there is no surcharge.

What are the main problems if exfiltration occurs?

Health Issue’s

In the USA the Centres for Disease Control and Prevention (CDC) and the US EPA regularly report on annual deaths due to sanitary sewer overflows. Sickness is widespread with the most common symptoms being diarrhea and nausea. This can be caused not only by drinking the water but also by swimming and eating shellfish and fish.

In the USA the Centres for Disease Control and Prevention (CDC) and the US EPA regularly report on annual deaths due to sanitary sewer overflows. Sickness is widespread with the most common symptoms being diarrhea and nausea. This can be caused not only by drinking the water but also by swimming and eating shellfish and fish.

Of greatest concern is infectious disease, such as the contamination of Wallis Lake oysters in Australia with the sewage-derived virus hepatitis.

In Baradine a small town in Australia The Department of Health reported a 30{f2ac4d1e1d40dc2e2d9280a1dfa90d854b2d8c80eba743affa37fc4ce2e16def} reduction in student sick days at the local school once a new vacuum system was installed. In far north tropical Queensland the introduction of a vacuum system led to a reduction is diseases caused by mosquitoes.

Not only is the health of the broader community at risk, there is also a risk for sewer operators needing to deal with overflows and backed up sewers.

Environmental Issue’s

In the nineties nearly 20{f2ac4d1e1d40dc2e2d9280a1dfa90d854b2d8c80eba743affa37fc4ce2e16def} of Florida’s manatee population died due to an algae bloom which had intensified due to sewer overflows.

On average 140 beaches in the US are closed or have warnings due to sewage contamination. KawaKawa Bay in New Zealand which had been a source of shellfish and a place to swim for the indigenous Maori population for hundreds of years was completely closed for ten years due to sewer overflows from a growing seaside community. It was only after a vacuum system was installed that the bay was reopened.

Sewage contamination readily degrades in the environment, but in water it can soak up oxygen from the waterway. Low oxygen levels can kill large numbers of fish and other aquatic life. Sewage also has toxic levels of ammonia that can poison aquatic life, along with many other contaminants.

Overflows contribute nutrients and sediment that encourage the vigorous growth of invasive weeds, such as willows, blackberries and privet, which often choke native species along stream channels and banks.

Aquaculture and Tourism Impact

Owners of Marina’s know the impact of attracting houseboats and tourists if sewage is contaminating the marina area, with bad smells putting off people going to local restaurants.

Owners of Marina’s know the impact of attracting houseboats and tourists if sewage is contaminating the marina area, with bad smells putting off people going to local restaurants.

Dal Lake, one of the most scenic tourist spots in Kashmir has suffered terribly from sewage overflows from nearby towns but even worse from raw sewage entering the lake from houseboats on the lake.

Tourists going to Brazil for the Olympics and the World Cup were told not to go near the beaches. Dr Daniel Becker, founder of the nonprofit Center for Health Promotion in Rio, said: ‘In Rio, if you’re going to the beach, you’re going to sewage.’

“A sewer line clogged with grease caused raw sewage to spill into the Five Mile River , forcing the closure of shellfish beds from Darien’s Long Neck Point to Wilson Point in Norwalk.” This is a common story, found around the world where sewage overflows can affect not only health but the livelihood of businesses.

Financial and Reputational

In many countries fines are being issued to water authorities if sewage overflows occur. The Environmental Protection Agencies must report any overflows and state and federal reporting is mandatory. If there is a death related to a sewage overflow that could of been prevented then lawsuits and possibly prison could affect senior people within the wastewater industry.

Newport Bay in California had to close its beach to swimmers and divers on one of its busiest weekends due to a large sewage spill that was caused by a sewage pump stopping, flooding the streets and beach. Not only was the beach closed for 4 days, ruining many tourists holidays, it also financially hurt local small businesses including restaurants who are talking about legal action against the Costa Mesa Sanitary District. The District has now been fined $503,000 by the regulators of The Santa Ana Regional Water Quality Control Board. Sadly it didn’t end there with a smaller spill caused by tree roots blocking a sewer main causing beaches to close for three days the following year.

There are always lots of big fish down at the lake because.

The first problem, is how do you know that you have a leak or overflow.Usually it is because sewage has been spotted at the local playground/beach/street. Or because you know from flow meters at the Treatment Plant that not all the flow is reaching it. In New Delhi it is estimated that only 60{f2ac4d1e1d40dc2e2d9280a1dfa90d854b2d8c80eba743affa37fc4ce2e16def} of all sewage collected is actually reaching the treatment plant.

Even with new technologies it is difficult to find leaks when the pipes are buried 10 metres (40 feet) underground. It is also very expensive to fix that leak. Not only is there potentially a disruption to service, a closing of roads the restoration of the surface, you need to find an allocation in the budget to make those repairs.

Why doesn’t all this happen with a vacuum sewer?

Well admittedly, homeowners can still create overflows at the home and badly maintained systems will always have problems. Modern wireless and cable monitoring systems reduce this risk considerably and is a game changer.

Well admittedly, homeowners can still create overflows at the home and badly maintained systems will always have problems. Modern wireless and cable monitoring systems reduce this risk considerably and is a game changer.

Firstly though, all vacuum mains are fairly small diameter, 125, 160, 200 dia (6,8,10 inches) and laid at a very shallow depth (Under 1.5m or 6 feet) So if there is ever a break it can be reached quickly and repaired without loss of service or expensive restoration. All pipework has to be pressure rated so it is a lot thicker than traditional sewer pipe.

Sewage is transported quickly in the pipe by air. The pipe is full mainly of air and not sewage. Large sections of the pipe are empty with sewage only collecting at lifts in the system. All pipework is under a negative pressure created at the pump station. If a pipe breaks, it sucks in and does not let any water leak out.

Once there is a leak or break in a pipe, the vacuum pump at the vacuum pump station must run longer. This creates an alarm which is transmitted to the operator. He is made aware that a leak is occurring in the system, this may be at the vacuum pump station, at a valve pit or in the pipework. A reticulation monitoring system will automatically notify the operator if there is something blocked in a valve or there is a break in the line. When pressure is monitored at each pit it is easy to detect in which section between two pits a break has occurred.

If a break has occurred, it would usually be due to an outside contractor breaking the pipe, tree roots rarely get into vacuum mains as they are pressure pipes. As a break is at minimum depth it is easy to locate and repair and no sewage would have leaked out.

If a blockage has occurred and sewage is backing up in the pit it cannot overflow through the manhole cover as there is a partition between the sump and cover preventing sewage from flooding at this point. If it starts to back up towards the house a high level alarm in the pit sends an urgent alarm to an operator who attends to the problem. If the problem is hard to solve or an experienced operator is not available a suction truck can be used at this point.

If a blockage has occurred and sewage is backing up in the pit it cannot overflow through the manhole cover as there is a partition between the sump and cover preventing sewage from flooding at this point. If it starts to back up towards the house a high level alarm in the pit sends an urgent alarm to an operator who attends to the problem. If the problem is hard to solve or an experienced operator is not available a suction truck can be used at this point.

At the Eco Resort near the Barrier Reef in Australia a vacuum system was chosen to ensure that no sewage could affect the local ecology nor leak into the swimming lagoons which would have closed the resort.

As any leak in the pipework, must be repaired immediately, no stormwater can enter the system during wet weather events. This is common in gravity systems where breaks may go unnoticed. This means that the vacuum system can never be inundated with stormwater and wet weather infiltration is not included in design parameters.

Due to the velocity of water in the pipes there is not build up of fats or grease and wet wipes or other objects do not cause blockages at the vacuum valve nor in the pit. See Video for information.

Vacuum Sewers are considered to be the Low Cost of Sewage collection, both in capital costs and also in maintenance costs. Risk is a very important consideration.

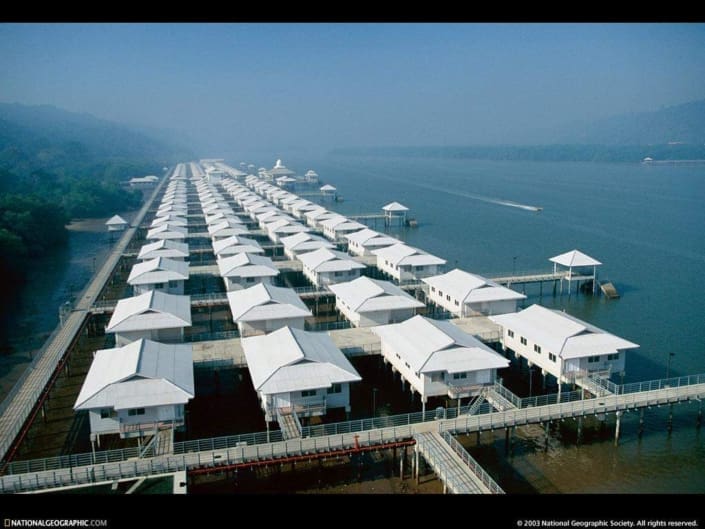

Kampong Ayer in Brunei’s capital city of Bandar Seri Begawan is a cluster of around 40 small villages connected by a 38-kilometer (23-mile) boardwalk. It dates back more than 600 years. Today, around 13,000 people live in the water village, about 3{f2ac4d1e1d40dc2e2d9280a1dfa90d854b2d8c80eba743affa37fc4ce2e16def} of the country’s population.

Kampong Ayer in Brunei’s capital city of Bandar Seri Begawan is a cluster of around 40 small villages connected by a 38-kilometer (23-mile) boardwalk. It dates back more than 600 years. Today, around 13,000 people live in the water village, about 3{f2ac4d1e1d40dc2e2d9280a1dfa90d854b2d8c80eba743affa37fc4ce2e16def} of the country’s population. Although some of the houses are now on vacuum sewer networks, many have still not been connected. Historically having raw sewerage drop into the water below only really affected the health of the local population as many of the water people swam or fished in the same water. With the wealth of those living in the villages increasing, more problems have surfaced with detergents entering the waterways, killing off the fish and other local seafood. None of this is good for tourism, especially the odour.

Although some of the houses are now on vacuum sewer networks, many have still not been connected. Historically having raw sewerage drop into the water below only really affected the health of the local population as many of the water people swam or fished in the same water. With the wealth of those living in the villages increasing, more problems have surfaced with detergents entering the waterways, killing off the fish and other local seafood. None of this is good for tourism, especially the odour. The pipework sloping to a gravity main below the houses close to the surface of the water was cut many times by local residents as it was impeding the way that many residents got around the area in their boats. For hundreds of years the residents drove their small boats under their houses and around the village. All of a sudden plastic pipes were in the way. A simple solution – cut them.

The pipework sloping to a gravity main below the houses close to the surface of the water was cut many times by local residents as it was impeding the way that many residents got around the area in their boats. For hundreds of years the residents drove their small boats under their houses and around the village. All of a sudden plastic pipes were in the way. A simple solution – cut them. As the pipework was laid directly under the walkways it was not visible and did not impact on the passage of the residents. The number one lesson for residents was to learn not to use their toilet as a rubbish bin. Initially blockages were common and operators grew frustrated by the number of items thrown into the system. The problem residents were easily found as with only 4 houses connected to a sump, the process of elimination was easy and the residents were educated as to proper use. Modern valve monitoring systems will make this even easier.

As the pipework was laid directly under the walkways it was not visible and did not impact on the passage of the residents. The number one lesson for residents was to learn not to use their toilet as a rubbish bin. Initially blockages were common and operators grew frustrated by the number of items thrown into the system. The problem residents were easily found as with only 4 houses connected to a sump, the process of elimination was easy and the residents were educated as to proper use. Modern valve monitoring systems will make this even easier.

There are space for 1200 animals on Ås farm, which consists of five buildings totaling 16,400 square meters . Small sheep (sheep and goats) have been accommodated in an airy barn of 1630 sqm, while the pigs have got their own 1740 sqm building with warmth in the floor. The entire livestock unit of 7140 sqm is equipped with two fully automatic milking robots, an advanced robot that can supply feed to the cows throughout the day.

There are space for 1200 animals on Ås farm, which consists of five buildings totaling 16,400 square meters . Small sheep (sheep and goats) have been accommodated in an airy barn of 1630 sqm, while the pigs have got their own 1740 sqm building with warmth in the floor. The entire livestock unit of 7140 sqm is equipped with two fully automatic milking robots, an advanced robot that can supply feed to the cows throughout the day. The STATSBYGG design group chose to work with Flovac after a close study of the Veterinary University of Hanover’s epidemic disease prevention unit’s use of the Flovac vacuum sewerage system installed in 2015. They cited the speed of installation, flexibility and that there had been virtually no operational issues and no contamination occurrences as the reason for choosing Flovac.

The STATSBYGG design group chose to work with Flovac after a close study of the Veterinary University of Hanover’s epidemic disease prevention unit’s use of the Flovac vacuum sewerage system installed in 2015. They cited the speed of installation, flexibility and that there had been virtually no operational issues and no contamination occurrences as the reason for choosing Flovac. A number of tests on the vacuum system were done, including a leakage test to show that if the vacuum mains were broken in anyway there would still be no blockage. A video of that test is available here if you would like to watch it.

A number of tests on the vacuum system were done, including a leakage test to show that if the vacuum mains were broken in anyway there would still be no blockage. A video of that test is available here if you would like to watch it.

A FLOVAC delegation was recently in Chile, in the Llay-Llay commune, where the first vacuum sewerage installation of the country is being built. As this technology is innovative for the Chilean technicians, a conference was organized for everyone interested in FLOVAC’s system, having it coincide with the formation day of the Regional Development Subsecretary (SUBDERE).

A FLOVAC delegation was recently in Chile, in the Llay-Llay commune, where the first vacuum sewerage installation of the country is being built. As this technology is innovative for the Chilean technicians, a conference was organized for everyone interested in FLOVAC’s system, having it coincide with the formation day of the Regional Development Subsecretary (SUBDERE).

For the regional manager of Subdere Valparaíso, Eduardo Pasten, the pioneering and innovative project that is implemented in Llay Llay, can be replicated in other cities of the country. He emphasizes the importance of the presence of representatives from all over Chile, “in order to be able to disseminate, and if applicable in the regions, to implement it,” Pasten said.

For the regional manager of Subdere Valparaíso, Eduardo Pasten, the pioneering and innovative project that is implemented in Llay Llay, can be replicated in other cities of the country. He emphasizes the importance of the presence of representatives from all over Chile, “in order to be able to disseminate, and if applicable in the regions, to implement it,” Pasten said. Another important consideration was the low amount of power that is required for the vacuum pump station. With power required only at the vacuum pump station a back up generator can easily be supplied if there is any interruption to local power supplies.

Another important consideration was the low amount of power that is required for the vacuum pump station. With power required only at the vacuum pump station a back up generator can easily be supplied if there is any interruption to local power supplies.

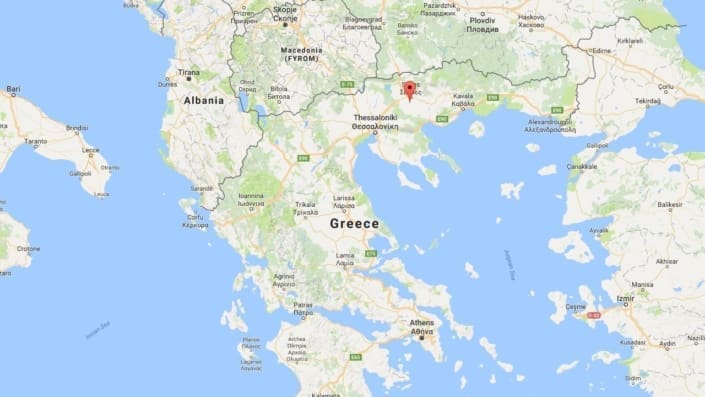

Flovac Greece has just completed the largest vacuum sewerage system ever undertaken in Greece covering the towns of Mitrousi and Skoutari in the Serres Region of northern Greece.

Flovac Greece has just completed the largest vacuum sewerage system ever undertaken in Greece covering the towns of Mitrousi and Skoutari in the Serres Region of northern Greece. The Serres region is an environmentally important area which won a European sustainable tourism award for aquatourism. A large artificial lake, Lake Kerkini was created nearby to make use of the extensive marshlands in the area. This is also behind the need for vacuum sewers in the villages as the water table is very high and actually visible on the surface in some areas.

The Serres region is an environmentally important area which won a European sustainable tourism award for aquatourism. A large artificial lake, Lake Kerkini was created nearby to make use of the extensive marshlands in the area. This is also behind the need for vacuum sewers in the villages as the water table is very high and actually visible on the surface in some areas.

Nearly all vacuum sewerage systems are found in coastal area’s many of which are subject to flooding from rain/storms or rising sea levels. We all understand the problems that occur if I&I is present, we all know what causes it to occur.

Nearly all vacuum sewerage systems are found in coastal area’s many of which are subject to flooding from rain/storms or rising sea levels. We all understand the problems that occur if I&I is present, we all know what causes it to occur.

As technology has improved, many asset managers have embraced the ability to locate exactly where and when I&I may be occurring. A sensor on a vacuum valve giving the open/close status will also be able to tell the operator the number of activations in a day. It is very easy for the operator to set up an alert to advise if any particular valve is operating more frequently than the general average, especially during wet weather events.

As technology has improved, many asset managers have embraced the ability to locate exactly where and when I&I may be occurring. A sensor on a vacuum valve giving the open/close status will also be able to tell the operator the number of activations in a day. It is very easy for the operator to set up an alert to advise if any particular valve is operating more frequently than the general average, especially during wet weather events. When designing a gravity sewer consideration must be made for Infiltration and Inflow on the pipes, the pump stations and the treatment plant.

When designing a gravity sewer consideration must be made for Infiltration and Inflow on the pipes, the pump stations and the treatment plant.

This historic village nestled on the banks of the Loire River near the French city of Nantes on the Atlantic coast of France is the site of the latest Flovac system in Europe.

This historic village nestled on the banks of the Loire River near the French city of Nantes on the Atlantic coast of France is the site of the latest Flovac system in Europe. The town is in the heart of an important agricultural area and has very flat and sandy soil, ideal for a vacuum system. It is also known as the town that first developed the beurre blanc sauce, often used in french cuisine. There are also vines on the hills around the town that grow a muscadet wine that is very popular.

The town is in the heart of an important agricultural area and has very flat and sandy soil, ideal for a vacuum system. It is also known as the town that first developed the beurre blanc sauce, often used in french cuisine. There are also vines on the hills around the town that grow a muscadet wine that is very popular. The system is able to be installed with only a single vacuum pump station which is also important in an old town like Saint Julien in that space is a precious commodity. It was also important to keep energy use as low as possible, and with a single small vacuum pump station, this is possible.

The system is able to be installed with only a single vacuum pump station which is also important in an old town like Saint Julien in that space is a precious commodity. It was also important to keep energy use as low as possible, and with a single small vacuum pump station, this is possible.

Gravity sewers have been used for hundreds of years, but they come at a much higher cost than many options reports accurately record. When selecting what type of sewerage system to use, take into account the risks associated with the solution. What happens if a sewer overflows? What happens if a storm or large wet weather event occurs. What will happen if a pipe breaks. What will be the cost and what will be the risk? A vacuum sewer could be far cheaper than you realise.

Gravity sewers have been used for hundreds of years, but they come at a much higher cost than many options reports accurately record. When selecting what type of sewerage system to use, take into account the risks associated with the solution. What happens if a sewer overflows? What happens if a storm or large wet weather event occurs. What will happen if a pipe breaks. What will be the cost and what will be the risk? A vacuum sewer could be far cheaper than you realise. Sewage leaks can occur for a number of reasons. the most common is leaking sewer pipes (this may be caused by tree roots or ground movement). A break in a gravity line can remain undetected for months or even years. In a Low Pressure Pump system a break will lead to a surcharging sewer which will be difficult to repair and costly.

Sewage leaks can occur for a number of reasons. the most common is leaking sewer pipes (this may be caused by tree roots or ground movement). A break in a gravity line can remain undetected for months or even years. In a Low Pressure Pump system a break will lead to a surcharging sewer which will be difficult to repair and costly. In the USA the

In the USA the  Owners of Marina’s know the impact of attracting houseboats and tourists if sewage is contaminating the marina area, with bad smells putting off people going to local restaurants.

Owners of Marina’s know the impact of attracting houseboats and tourists if sewage is contaminating the marina area, with bad smells putting off people going to local restaurants. Well admittedly, homeowners can still create overflows at the home and badly maintained systems will always have problems. Modern wireless and cable monitoring systems reduce this risk considerably and is a game changer.

Well admittedly, homeowners can still create overflows at the home and badly maintained systems will always have problems. Modern wireless and cable monitoring systems reduce this risk considerably and is a game changer. If a blockage has occurred and sewage is backing up in the pit it cannot overflow through the manhole cover as there is a partition between the sump and cover preventing sewage from flooding at this point. If it starts to back up towards the house a high level alarm in the pit sends an urgent alarm to an operator who attends to the problem. If the problem is hard to solve or an experienced operator is not available a suction truck can be used at this point.

If a blockage has occurred and sewage is backing up in the pit it cannot overflow through the manhole cover as there is a partition between the sump and cover preventing sewage from flooding at this point. If it starts to back up towards the house a high level alarm in the pit sends an urgent alarm to an operator who attends to the problem. If the problem is hard to solve or an experienced operator is not available a suction truck can be used at this point.

The municipality is located just south of the capital

The municipality is located just south of the capital  A gravity system would have required dozens of gravity pump stations due to the high water table while only 6 Vacuum Pump Stations were needed. This has reduced the energy cost of the system and also reduced the maintenance cost. As the area sometimes suffers power outages the ability to have backup generators at each station allowed for unrestricted service for homeowners. The Vacuum Pump Stations have both duty and standby pumps and are fully monitored back to base.

A gravity system would have required dozens of gravity pump stations due to the high water table while only 6 Vacuum Pump Stations were needed. This has reduced the energy cost of the system and also reduced the maintenance cost. As the area sometimes suffers power outages the ability to have backup generators at each station allowed for unrestricted service for homeowners. The Vacuum Pump Stations have both duty and standby pumps and are fully monitored back to base.

To understand some of the problems you need go no further than googling “Plum Island frozen sewers”. The main problems seemed to be related to frozen vacuum valves, water frozen in the pits, gooseneck vents submerged by snow, frozen sewage in the pipework, frozen gate valves and division valves and leaks in the line.

To understand some of the problems you need go no further than googling “Plum Island frozen sewers”. The main problems seemed to be related to frozen vacuum valves, water frozen in the pits, gooseneck vents submerged by snow, frozen sewage in the pipework, frozen gate valves and division valves and leaks in the line. When dealing in area’s subject to extreme cold we need to take care of how deep the vacuum mains are laid, what type of division valves are used, how the collection pit is designed, where the air intake vent should be for the operation of the valve. Many of these things can be adjusted in existing systems.

When dealing in area’s subject to extreme cold we need to take care of how deep the vacuum mains are laid, what type of division valves are used, how the collection pit is designed, where the air intake vent should be for the operation of the valve. Many of these things can be adjusted in existing systems. The monitoring system also makes it very easy for operators to locate the exact location of collection pits. This is also true in coastal area’s where pits can often be covered by sand during the summer months.

The monitoring system also makes it very easy for operators to locate the exact location of collection pits. This is also true in coastal area’s where pits can often be covered by sand during the summer months.