First Flovac Project in Vietnam – The Ana Marina in Nha Trang

The Riviera of the South China Sea

Vietnam’s first marina is nearing completion, and will include Flovac’s first vacuum system in the country. Upon completion it will contain berths for over two hundred yachts and Super-yachts. Ana Marina in Nha Trang on the south east coast of Vietnam will be the country’s first world class marina, initially offering 60 berths for vessels of 20-40m and extra wide berths for catamarans.

Future phases will include a super yacht dock for six yachts up to 70m in length and an additional 100m berth is under consideration. The remaining berths, to bring the overall total to 220, will accommodate yachts of 10 to 20m and will be operational by 2021.

General Manager of the project, Ruurd Van Putten, gave us his insight. “It’s a unique project in Vietnam that will ignite a whole new industry. Yachting is generally known for its high standard, quality and innovation. Marinas have proven to be a catalyst for economic growth, development of tourism and overall improvement of leisure services and facilities.

General Manager of the project, Ruurd Van Putten, gave us his insight. “It’s a unique project in Vietnam that will ignite a whole new industry. Yachting is generally known for its high standard, quality and innovation. Marinas have proven to be a catalyst for economic growth, development of tourism and overall improvement of leisure services and facilities.

With environmental concerns a high priority in coastal developments, Ana Marina is heavily focused on the key concepts of Sustainability, Durability and Responsibility. “A marina means less pollution, cleaner water, and protection to vulnerable marine life. It will have special systems to prevent spillage of oil, fuel and waste of boats.

With environmental concerns a high priority in coastal developments, Ana Marina is heavily focused on the key concepts of Sustainability, Durability and Responsibility. “A marina means less pollution, cleaner water, and protection to vulnerable marine life. It will have special systems to prevent spillage of oil, fuel and waste of boats.

This will result in better water quality allowing plants, coral and fish to grow un-threatened, and also a safe and clean area to swim and play. We are dedicated to raising awareness that the sea is the beating heart and lifeline of Nha Trang, and must be preserved and protected at all costs”, Ruurd concluded.

A Flovac Vacuum Marina system was chosen as it has been demonstrated that it can provide certainty around the environmental benefits that the client has determined to be of absolute importance. Flovac marina systems have been installed in a number of high profile areas including in Barcelona, Greece, Italy and the Caribbean.

The Flovac systems look after boats of all sizes and can include the handling of bilge water and oil separation. The larger Superyachts pump their wastewater or bilgewater into a Flovac collection chamber which can be sized and designed to fit into the marina area.

For smaller boats a pillar that often houses water and power will have a connection point for a hose that will suck the wastewater from the boats. This is often done by the marina operator or can also be via a key card or code-pad operation by the boat owner. Flovac has initially supplied 9 pillars to the project and all are connected to a single vacuum pump station. All of the pillars will be located on floating pontoons.

The main benefits of the Flovac vacuum sewerage system is that it will not leak into the water and is very easy to install. All points of the system are fully monitored from the central command center as so easily managed. To see more details of our marina systems please go to this page.

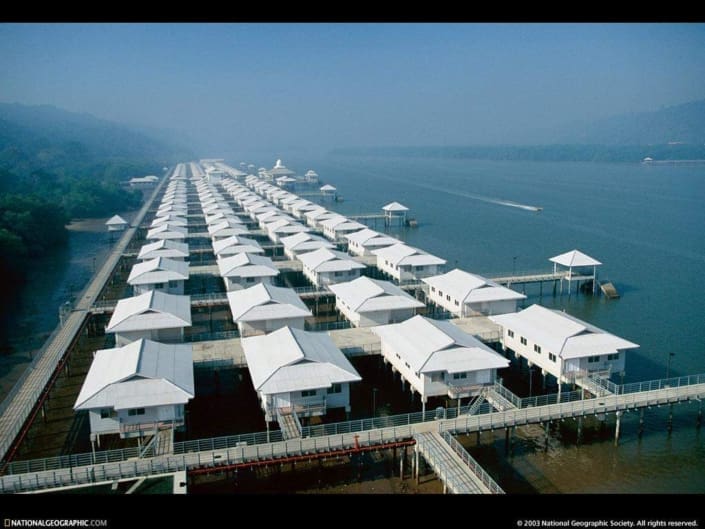

Kampong Ayer in Brunei’s capital city of Bandar Seri Begawan is a cluster of around 40 small villages connected by a 38-kilometer (23-mile) boardwalk. It dates back more than 600 years. Today, around 13,000 people live in the water village, about 3{f2ac4d1e1d40dc2e2d9280a1dfa90d854b2d8c80eba743affa37fc4ce2e16def} of the country’s population.

Kampong Ayer in Brunei’s capital city of Bandar Seri Begawan is a cluster of around 40 small villages connected by a 38-kilometer (23-mile) boardwalk. It dates back more than 600 years. Today, around 13,000 people live in the water village, about 3{f2ac4d1e1d40dc2e2d9280a1dfa90d854b2d8c80eba743affa37fc4ce2e16def} of the country’s population. Although some of the houses are now on vacuum sewer networks, many have still not been connected. Historically having raw sewerage drop into the water below only really affected the health of the local population as many of the water people swam or fished in the same water. With the wealth of those living in the villages increasing, more problems have surfaced with detergents entering the waterways, killing off the fish and other local seafood. None of this is good for tourism, especially the odour.

Although some of the houses are now on vacuum sewer networks, many have still not been connected. Historically having raw sewerage drop into the water below only really affected the health of the local population as many of the water people swam or fished in the same water. With the wealth of those living in the villages increasing, more problems have surfaced with detergents entering the waterways, killing off the fish and other local seafood. None of this is good for tourism, especially the odour. The pipework sloping to a gravity main below the houses close to the surface of the water was cut many times by local residents as it was impeding the way that many residents got around the area in their boats. For hundreds of years the residents drove their small boats under their houses and around the village. All of a sudden plastic pipes were in the way. A simple solution – cut them.

The pipework sloping to a gravity main below the houses close to the surface of the water was cut many times by local residents as it was impeding the way that many residents got around the area in their boats. For hundreds of years the residents drove their small boats under their houses and around the village. All of a sudden plastic pipes were in the way. A simple solution – cut them. As the pipework was laid directly under the walkways it was not visible and did not impact on the passage of the residents. The number one lesson for residents was to learn not to use their toilet as a rubbish bin. Initially blockages were common and operators grew frustrated by the number of items thrown into the system. The problem residents were easily found as with only 4 houses connected to a sump, the process of elimination was easy and the residents were educated as to proper use. Modern valve monitoring systems will make this even easier.

As the pipework was laid directly under the walkways it was not visible and did not impact on the passage of the residents. The number one lesson for residents was to learn not to use their toilet as a rubbish bin. Initially blockages were common and operators grew frustrated by the number of items thrown into the system. The problem residents were easily found as with only 4 houses connected to a sump, the process of elimination was easy and the residents were educated as to proper use. Modern valve monitoring systems will make this even easier.

If you are part of a coastal community it could be worse, your old broken pipes could be letting seawater into the system every time there is a high tide or major storm. Salt water can cause major problems at the Treatment Plant. For communities like Miami Beach who get storm surges flooding their sewers and closing their beach on an increasingly regular basis it can cause major economic and health risks. Santa Pola in the Alicante area of Spain found that the impact of global warming and rising sea levels caused a complete failure of their old sewer system.

If you are part of a coastal community it could be worse, your old broken pipes could be letting seawater into the system every time there is a high tide or major storm. Salt water can cause major problems at the Treatment Plant. For communities like Miami Beach who get storm surges flooding their sewers and closing their beach on an increasingly regular basis it can cause major economic and health risks. Santa Pola in the Alicante area of Spain found that the impact of global warming and rising sea levels caused a complete failure of their old sewer system. The town of Santa Pola with over 10,000 homes replaced their whole gravity sewer system with a Flovac vacuum sewerage system. As vacuum mains are laid in shallow trenches it was possible to skirt around, above and below exiting infrastructure and eventually replace the network.

The town of Santa Pola with over 10,000 homes replaced their whole gravity sewer system with a Flovac vacuum sewerage system. As vacuum mains are laid in shallow trenches it was possible to skirt around, above and below exiting infrastructure and eventually replace the network.  When looking at upgrading a gravity sewer, pipe relining can be an option, but in many cases this becomes an ongoing expensive option and be too difficult in a large network. Some utilities just look to replace the old pipework, but in most communities this is just not practical. This could mean uprooted gardens, roads out of use for a number of months, noise, dust and a huge cost.

When looking at upgrading a gravity sewer, pipe relining can be an option, but in many cases this becomes an ongoing expensive option and be too difficult in a large network. Some utilities just look to replace the old pipework, but in most communities this is just not practical. This could mean uprooted gardens, roads out of use for a number of months, noise, dust and a huge cost. Flovac vacuum sewers have shown time and again, their versatility. This means either their ability to handle density changes or climate changes. It might even mean changes in ground conditions as happened in Christchurch New Zealand when they suffered from a terrible earthquake. The old gravity sewers in the city and surrounding suburbs broke and left residents with no service for months. Vacuum sewers have now replaced a large portion of the gravity sewers in Christchurch and although difficult has proved to be a better long term solution for the residents and operators.

Flovac vacuum sewers have shown time and again, their versatility. This means either their ability to handle density changes or climate changes. It might even mean changes in ground conditions as happened in Christchurch New Zealand when they suffered from a terrible earthquake. The old gravity sewers in the city and surrounding suburbs broke and left residents with no service for months. Vacuum sewers have now replaced a large portion of the gravity sewers in Christchurch and although difficult has proved to be a better long term solution for the residents and operators.

As the project was quite remote Flovac supplied a containerized plug and play vacuum pump station and treatment plant. All water on the island is supplied by a desalination plant, so water is precious and spared as much as possible. Treatment quality is very important so that this pristine area is not polluted in any way.

As the project was quite remote Flovac supplied a containerized plug and play vacuum pump station and treatment plant. All water on the island is supplied by a desalination plant, so water is precious and spared as much as possible. Treatment quality is very important so that this pristine area is not polluted in any way.

A high profile project and one of the largest scale vacuum sewerage systems ever designed had an official opening this month in Bahrain for its key resort project.

A high profile project and one of the largest scale vacuum sewerage systems ever designed had an official opening this month in Bahrain for its key resort project.

There are space for 1200 animals on Ås farm, which consists of five buildings totaling 16,400 square meters . Small sheep (sheep and goats) have been accommodated in an airy barn of 1630 sqm, while the pigs have got their own 1740 sqm building with warmth in the floor. The entire livestock unit of 7140 sqm is equipped with two fully automatic milking robots, an advanced robot that can supply feed to the cows throughout the day.

There are space for 1200 animals on Ås farm, which consists of five buildings totaling 16,400 square meters . Small sheep (sheep and goats) have been accommodated in an airy barn of 1630 sqm, while the pigs have got their own 1740 sqm building with warmth in the floor. The entire livestock unit of 7140 sqm is equipped with two fully automatic milking robots, an advanced robot that can supply feed to the cows throughout the day. The STATSBYGG design group chose to work with Flovac after a close study of the Veterinary University of Hanover’s epidemic disease prevention unit’s use of the Flovac vacuum sewerage system installed in 2015. They cited the speed of installation, flexibility and that there had been virtually no operational issues and no contamination occurrences as the reason for choosing Flovac.

The STATSBYGG design group chose to work with Flovac after a close study of the Veterinary University of Hanover’s epidemic disease prevention unit’s use of the Flovac vacuum sewerage system installed in 2015. They cited the speed of installation, flexibility and that there had been virtually no operational issues and no contamination occurrences as the reason for choosing Flovac. A number of tests on the vacuum system were done, including a leakage test to show that if the vacuum mains were broken in anyway there would still be no blockage. A video of that test is available here if you would like to watch it.

A number of tests on the vacuum system were done, including a leakage test to show that if the vacuum mains were broken in anyway there would still be no blockage. A video of that test is available here if you would like to watch it.