How to identify 5,000,000 litres per year of salt water entering your sewer network at a single glance

For many coastal communities, infiltration from stormwater and inflow from ground water (I&I) causes major problems. Not only are systems not designed to handle large extra flows, but the additional power costs and operational problems can bring a network to its knees.

St Huberts Island

The coastal community of St Huberts on the central coast of New South Wales in Australia is a beautiful town, surrounded by fantastic fishing spots and has a very high water table. As is common in these coastal communities a vacuum sewer system has been installed to handle the wastewater from the houses. The system was installed in the mid nineties and over the years there has been an increase of I&I into the system.

Vacuum systems are usually installed in high water table areas because they are less susceptible to infiltration than are gravity systems. Over time homeowners gravity pipes and even old collection pits can break and allow ground water to enter the system.

Central Coast council realised that they had a problem which left their residents vulnerable to a loss of service and hire Flovac to come up with a solution that would help locate areas within the network where stormwater was entering the network.

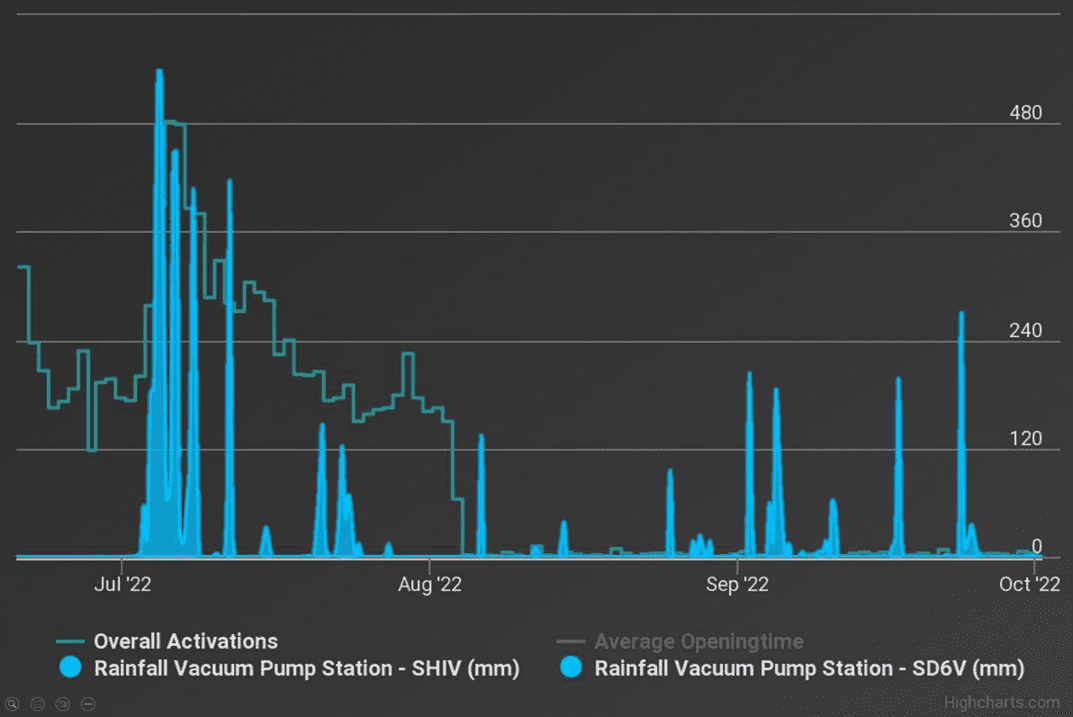

Flovacs monitoring system was installed and within weeks it became evident that the system was taking in water, not only during storm events, but also during high tides. Vacuum valves within the vacuum collection network operate pneumatically every time 40 litres of water enters the collection sump. In this community we would expect to see each valve operating 40-50 times per day or 2,000 litres. In the first month we noticed that one pit was activating between 200 and 500 times per day, even when it wasn’t raining. When it rained it activated even more. this represented between 10-17,000 litres of water every day.

The collection pits in most of this community were old and made out of fibreglass. Over the years there was some evidence of wear. when operators investigated this particular pit, highlighted by the monitoring system, they found that the floor of the pit was broken, allowing ground water to enter the sump. once discovered, the pit was replaced and you can see that from mid August the daily valve activations have reduced to only 10 activations per day as it was found that one of the houses connected was empty.

You can see from the video that water is entering the sump from the pit bottom and not from the incoming gravity line. As this is a high water table area, it was discovered that all of this water was salt water from the bay. each year this pit was adding at least 5 million litres of sea water to the system. A program is now in place to locate other points of infiltration.

The operators having had great success with this, also installed monitoring at a nearby town. After the first major storm, more than 20 collection pits had more than 300 activations each, a major amount of infiltration.

Without Flovacs monitoring system it would of been impossible to locate the problem

Contact Flovac to find out how we can solve your I&I problems.

monitoring technology is to provide the district with real-time alerts of system issues as a means of mitigating SSOs. The installation is expected to take approximately two years to complete and will utilize a basin-by-basin approach to make such a large-scale project manageable. The monitoring technology will be deployed throughout the district’s vacuum collection system, grinder pump collection systems and force mains. This includes nearly 3,000 collection pits.

monitoring technology is to provide the district with real-time alerts of system issues as a means of mitigating SSOs. The installation is expected to take approximately two years to complete and will utilize a basin-by-basin approach to make such a large-scale project manageable. The monitoring technology will be deployed throughout the district’s vacuum collection system, grinder pump collection systems and force mains. This includes nearly 3,000 collection pits.

The city of Eretrea in Greece, one of the best known Archaeological sites in the world, has had a much needed upgrade. A Flovac vacuum system has been installed to replace old septic tanks that still serviced the houses in the town.

The city of Eretrea in Greece, one of the best known Archaeological sites in the world, has had a much needed upgrade. A Flovac vacuum system has been installed to replace old septic tanks that still serviced the houses in the town.

One vacuum pump station will serve over 230 house connections. Over 12 km of PEAD PN 10 vacuum mains are being installed in the ground sized from 110 to 200mm. All the Flovac collection Pits are fitted out and tested prior to delivery to the project office.

One vacuum pump station will serve over 230 house connections. Over 12 km of PEAD PN 10 vacuum mains are being installed in the ground sized from 110 to 200mm. All the Flovac collection Pits are fitted out and tested prior to delivery to the project office.