Sandy Lane Yacht Club and Residences

Sandy Lane Yacht Club is the luxury marina that has made Canouan the yachting hub of the Grenadines. This large complex, which occupies the southern reaches of the Caribbean island of Canouan, has a total of 120 berths for yachts – 24 of which are for superyachts up to 100 meters in length -, a commercial area, hotels and a residential area. of luxury villas.

Sandy Lane Superyacht Marina and Residences

Flovac in charge of the design and installation of a vacuum sewer system and treatment plant that would serve the entire complex. As the resort is in a remote location where getting local materials easily, everything was pre-built in 2 x 40′ containers. These were pre-tested and placed onto a remote area of the complex and supplied with a generator to ensure no down time from any power outages.

The project, which lasted for two years, ended with a 2 km long sewage network, a vacuum station for the entire system and a reclaimed water treatment plant. All of this to supply both the marina and the complex’s buildings.

Containerized vacuum pump station and containerized treatment plant.

Management and supervisory software

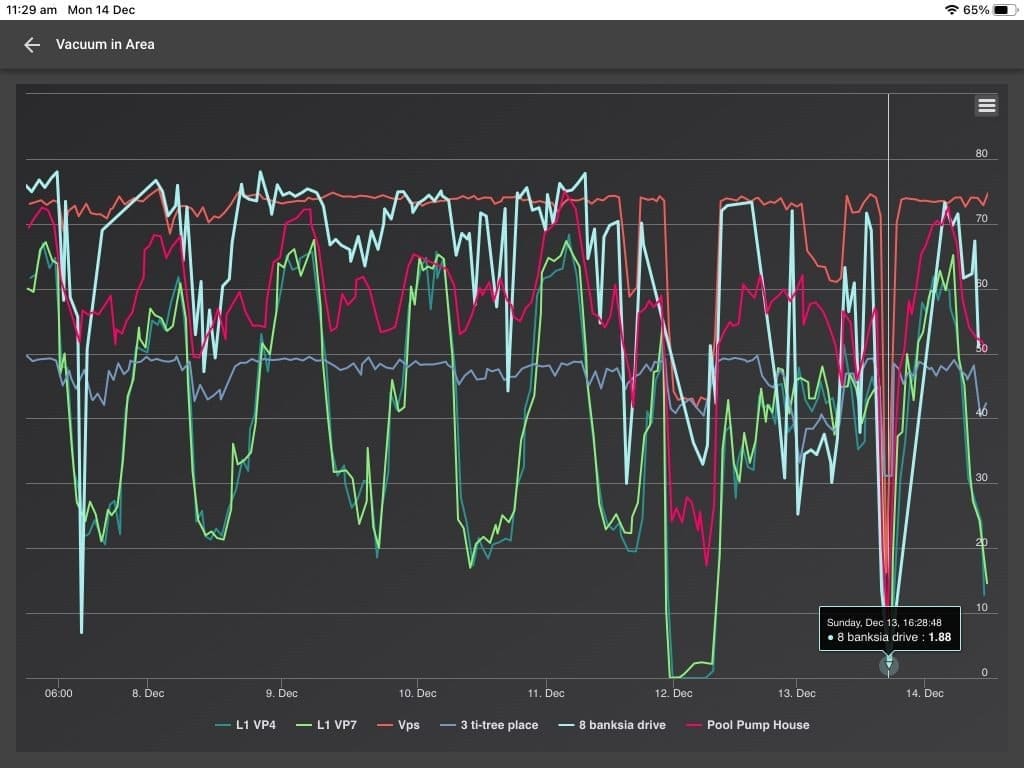

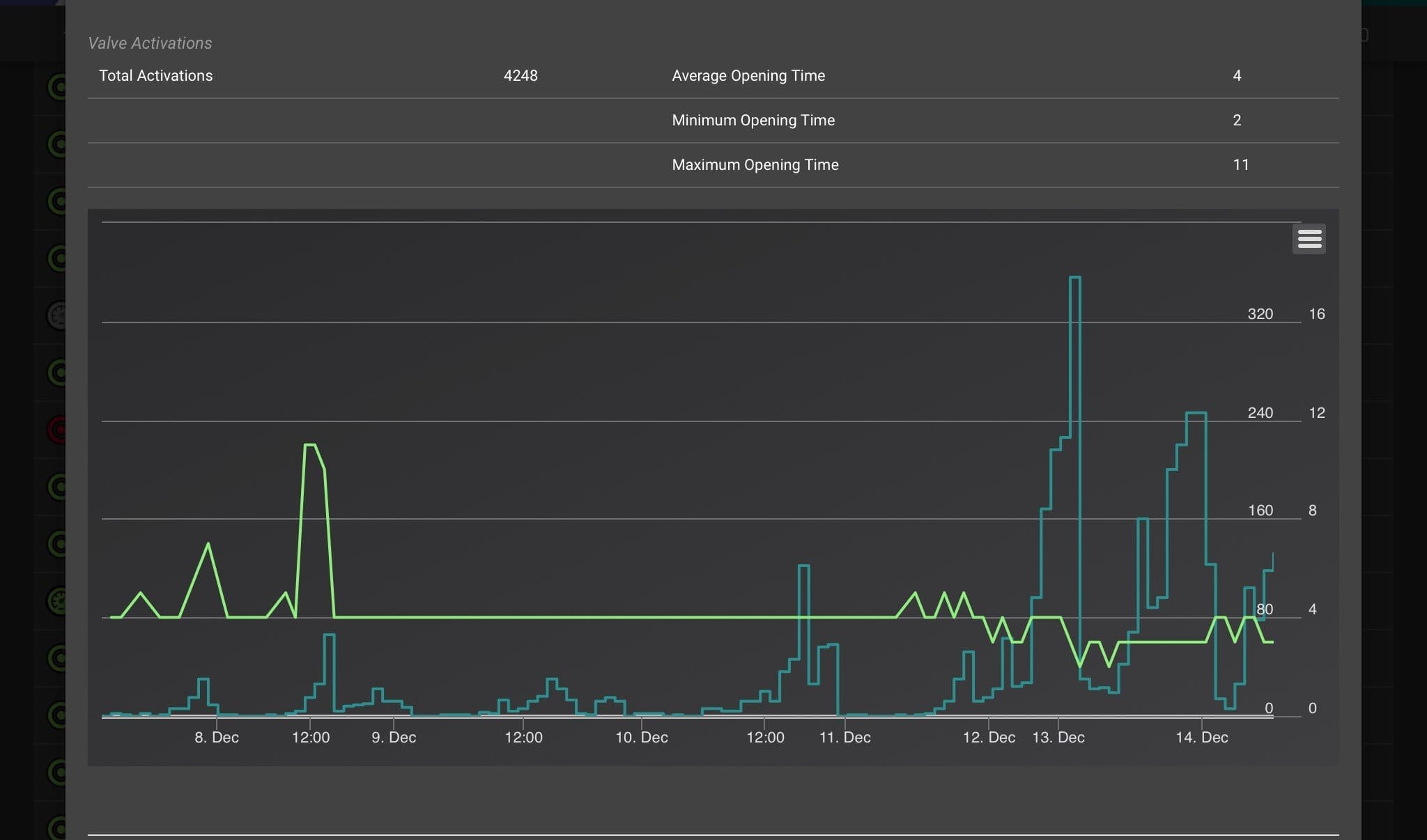

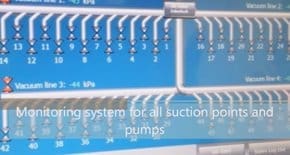

Flovac’s monitoring system is intelligent software – designed and developed by Flovac – for managing and monitoring vacuum sewer systems. The main function is to monitor the systems and identify any failure, infiltration, or malfunction in the sewer network.

With Flovacs wireless technology it is possible to supervise an installation from the same vacuum station, from its own control center at its headquarters, on any PDA device or even from a web server anywhere on the planet. The control can be easily adapted to SCADA’s, both new and existing.

Flovac can monitor the following aspects:

- The vacuum station. Among all the possible signals, the most important ones such as stop / start and safety sensors of the electrical-mechanical equipment, levels and process alarms, signals of the control devices and access control (security) stand out.

- The vacuum network. From a simple warning of the status of the division valves to controlling their operation on a PDA, as well as knowing the vacuum level at any point in the network with or without electrical connection.

- The vacuum valves. Knowing the status of each valve in the system, high level alarms, detection of outages and real-time alerts.

Flovac will integrate the monitoring to the BMS (Building Management System), the building management system that Sandy Lane Yacht Club has installed in its complex. This integration will allow the supervision and control of the status of all the buildings and facilities of the marina

Thanks to the Flovac software, it will be possible to obtain real-time knowledge of the state of the network, which will reduce the response time to possible incidents. Although there is backup equipment in case of emergency, the interaction of the operator with the system increases the reliability of the vacuum sewer system.

This type of monitoring has recently been installed at the Superyacht Marina in Sydney Harbour as well as at the Superyacht Marina at Fort Lauderdale in Florida.

Flovac is a leading supplier of vacuum sewerage systems to large scale marinas around the world. To find out more about our marina work and projects please Click here

If you would like more information please contact your closest Flovac office

Flovac is a proud member of the Marina Industries Association

The management team and operators at Willowbrook were particularly impressed with the speed of the evacuation of the trains as the process took a matter of seconds rather than the extensive delays that they have previously had.

The management team and operators at Willowbrook were particularly impressed with the speed of the evacuation of the trains as the process took a matter of seconds rather than the extensive delays that they have previously had. Flovac has now installed extraction systems for a number of clients in particular for the Deutsche Bahn’s ICE network, including systems in Frankfurt, Cologne and Dusseldorf.

Flovac has now installed extraction systems for a number of clients in particular for the Deutsche Bahn’s ICE network, including systems in Frankfurt, Cologne and Dusseldorf.

As we have seen with

As we have seen with

Raising Capacity

Raising Capacity

The Innovation team from Flovac’s German Unit under the management of Antje Adler has been appointed by Norway’s leading engineering design firm STATSBYGG to supply a Flovac vacuum sewerage system for inclusion in the new Center for Animal Research at Campus Ås. Based outside of Oslo, Campus Ås will become Norway’s largest interdisciplinary academic Center for the environmental and life sciences and for landscape architecture.

The Innovation team from Flovac’s German Unit under the management of Antje Adler has been appointed by Norway’s leading engineering design firm STATSBYGG to supply a Flovac vacuum sewerage system for inclusion in the new Center for Animal Research at Campus Ås. Based outside of Oslo, Campus Ås will become Norway’s largest interdisciplinary academic Center for the environmental and life sciences and for landscape architecture.

As disease control and prevention is of utmost importance, the Flovac system was chosen to ensure that any waste from the animals is collected in a safe way. A Flovac pump station which generates the vacuum pressure in the wastewater collection network is situated remotely from the animals with flexible pipe installed underneath the livestock units. All waste is collected via floor drains throughout the facility. Flovac valves are housed in the floor drains and operate pneumatically with no need for an electrical connection. This reduces the carbon footprint of the facility. To ensure as little disruption as possible for the livestock all valves are remotely monitored and crucial data can be collected by the management team.

As disease control and prevention is of utmost importance, the Flovac system was chosen to ensure that any waste from the animals is collected in a safe way. A Flovac pump station which generates the vacuum pressure in the wastewater collection network is situated remotely from the animals with flexible pipe installed underneath the livestock units. All waste is collected via floor drains throughout the facility. Flovac valves are housed in the floor drains and operate pneumatically with no need for an electrical connection. This reduces the carbon footprint of the facility. To ensure as little disruption as possible for the livestock all valves are remotely monitored and crucial data can be collected by the management team. A number of tests on the vacuum system were done, including a leakage test to show that if the vacuum mains were broken in anyway there would still be no blockage. A video of that test is available here if you would like to watch it.

A number of tests on the vacuum system were done, including a leakage test to show that if the vacuum mains were broken in anyway there would still be no blockage. A video of that test is available here if you would like to watch it.

At first a tender came out for a gravity system with a number of pump stations located along the rivers edge. When our colleagues from Flovac Polska contacted the town and contractor (designer) about the benefits of a vacuum system in this location, they were very unsure as they had never heard of vacuum system. After a whole of life costing analysis and discussions with the contractor about the capital costs it was clearly shown that the vacuum system would be a much cheaper option. More importantly a Flovac system was seen as a much better system to install in an area where flooding was a problem.

At first a tender came out for a gravity system with a number of pump stations located along the rivers edge. When our colleagues from Flovac Polska contacted the town and contractor (designer) about the benefits of a vacuum system in this location, they were very unsure as they had never heard of vacuum system. After a whole of life costing analysis and discussions with the contractor about the capital costs it was clearly shown that the vacuum system would be a much cheaper option. More importantly a Flovac system was seen as a much better system to install in an area where flooding was a problem.

The celebrated project was designed by engineering consultancy Harrison Grierson with Flovac Systems and constructed by Fulton Hogan. Watercare took over the operation of the Kawakawa Bay system after it had been in operation for a year. Following the implementation of the system, ageing septic tanks in the area could be removed, helping to reduce pollution to local streams and

The celebrated project was designed by engineering consultancy Harrison Grierson with Flovac Systems and constructed by Fulton Hogan. Watercare took over the operation of the Kawakawa Bay system after it had been in operation for a year. Following the implementation of the system, ageing septic tanks in the area could be removed, helping to reduce pollution to local streams and The wastewater project makes use of a Flovac vacuum collection system, which is a first for New Zealand. This allowed for the fast construction of shallow pipelines, reducing the impact on residents in the area.

The wastewater project makes use of a Flovac vacuum collection system, which is a first for New Zealand. This allowed for the fast construction of shallow pipelines, reducing the impact on residents in the area.