Grand Case St Martin Caribbean

When Hurricane Irma wreaked havoc through the Caribbean Islands in 2017 leaving a trail of destruction, it was clear that many towns would need to be completely rebuild many of their buildings but also their water and sewage infrastructure.

Having already been engaged in other Caribbean countries to install Flovac vacuum sewerage systems the engineers in Grand Case on Saint Martin approached Flovac to see if a vacuum sewerage system would be the best technology for the island.

This area is very flat and has a high water table, which meant that you could not dig more than one meter without finding salt water that would damage a system using gravity piping networks. Until now Grand Case had a network based on septic tanks that was not adequate. After the damage caused by Hurricane Irma, Saint Martin needed urgent repairs and a new, more efficient sanitation system. Work began in Grand Case (Saint Martin) towards the end of 2019 and it was clear that a vacuum sewerage system was essential in the area.

Shallow Vacuum Main Installation

Often working in narrow streets with other cables and pipes already installed it was clear that a vacuum system was the only system that could be installed with the least amount of impact on the local community. The people of Saint Martin were also very happy to hear that there would be no odors from the system as well as no potential of sewer leaks from the pipes.

As the region had experienced more major storms and hurricanes in recent years it was also important that the system was resilient and would still operate during extended power outages.

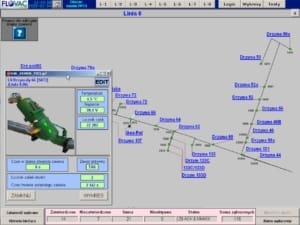

Being a remote community with little experience with vacuum sewer technology the local managers and operators were very happy that Flovac installed a monitoring system throughout the network that could be watched and supported by the Flovac operations group in Europe. If there is ever a low vacuum or breakdown, Flovac’s experienced operators could assist.

The main design and installation was handled by Flovac’s project group based out of Barcelona as they had recently installed a system nearby in Canouan. This group, headed by Bruno Galindo and Francisco Rodríguez is now supporting Saint Martin’s operators.

Grand Case St Martin

Flovac was asked to design and supply a vacuum system that would be able to handle the high flows that will ultimately be handled by the Resort. The vacuum system needed to facilitate not only the hotel but also residential areas, restaurants and the marina. The client was aware of the good work which Flovac had done at Reef Island in Bahrain and was particularly impressed with the monitoring system that had been installed. The monitoring allows operators to see exactly what was happening anywhere in the network including the operation of the vacuum pump station. Mr Willem Gooren one of the founders of Flovac managed the project and was based in the Middle East for extensive periods during the projects establishment and finalization.

Flovac was asked to design and supply a vacuum system that would be able to handle the high flows that will ultimately be handled by the Resort. The vacuum system needed to facilitate not only the hotel but also residential areas, restaurants and the marina. The client was aware of the good work which Flovac had done at Reef Island in Bahrain and was particularly impressed with the monitoring system that had been installed. The monitoring allows operators to see exactly what was happening anywhere in the network including the operation of the vacuum pump station. Mr Willem Gooren one of the founders of Flovac managed the project and was based in the Middle East for extensive periods during the projects establishment and finalization.

Another benefit of the vacuum sewer system is its ability to handle high flows into the collection system. A large supermarket complex is being planned in the neighbourhood complete with a Foodstuffs supermarket, cafe’s and restaurants. Already built is a large BP service station which houses a cafe and a Jetwash. The Flovac system handles the commercial premises and can handle any flows from the car washing facility.

Another benefit of the vacuum sewer system is its ability to handle high flows into the collection system. A large supermarket complex is being planned in the neighbourhood complete with a Foodstuffs supermarket, cafe’s and restaurants. Already built is a large BP service station which houses a cafe and a Jetwash. The Flovac system handles the commercial premises and can handle any flows from the car washing facility.

The whole system will have the latest in wireless monitoring at every collection pit.

The whole system will have the latest in wireless monitoring at every collection pit.