Superyacht Marina Sydney Australia

Sydney Superyacht Marina Sewage Pump Out System Upgrade

This standout marina was first built in the late nineties to accommodate visitors to the 2000 Sydney Olympics. Since that time, not only have the yachts gotten bigger but the requirements of many of the yacht owners have reached the point where a number of upgrades to facilities are required. Clemens Overdijk, the Marina Manager since 2016 has been very interested in ensuring that their customers get the best experience possible.

This standout marina was first built in the late nineties to accommodate visitors to the 2000 Sydney Olympics. Since that time, not only have the yachts gotten bigger but the requirements of many of the yacht owners have reached the point where a number of upgrades to facilities are required. Clemens Overdijk, the Marina Manager since 2016 has been very interested in ensuring that their customers get the best experience possible.

One aspect that is very important to many yacht owners is the ability to quickly and cleanly discharge any wastewater from their vessels. No one wants leaks or the risk of overflows, or odours and importantly no one wants to spend hours tied up discharging wastewater. Or even worse needing to go to a different marina to discharge. There are many smaller marinas now unable to handle the size of the tanks, or the depth of the yachts, causing them to go elsewhere, at quite a cost. An important bonus for the yacht owners is that each berth offers a direct connection to the vacuum system.

Clemens looked at a variety of solutions from around the world and found that Flovac, a local company, was doing large scale marina sewage systems at a number of large marinas around the world and catering to the largest of yachts. These included projects in Barcelona, Spain, Italy and Greece, home of the superyachts.

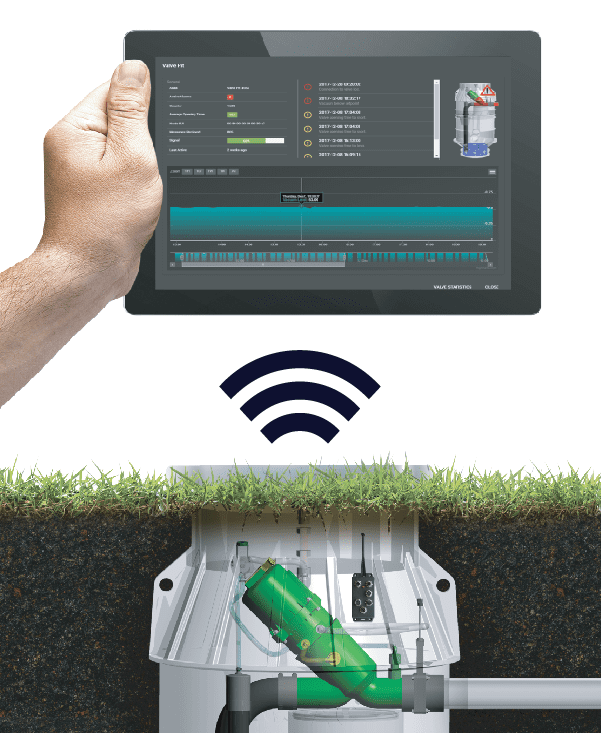

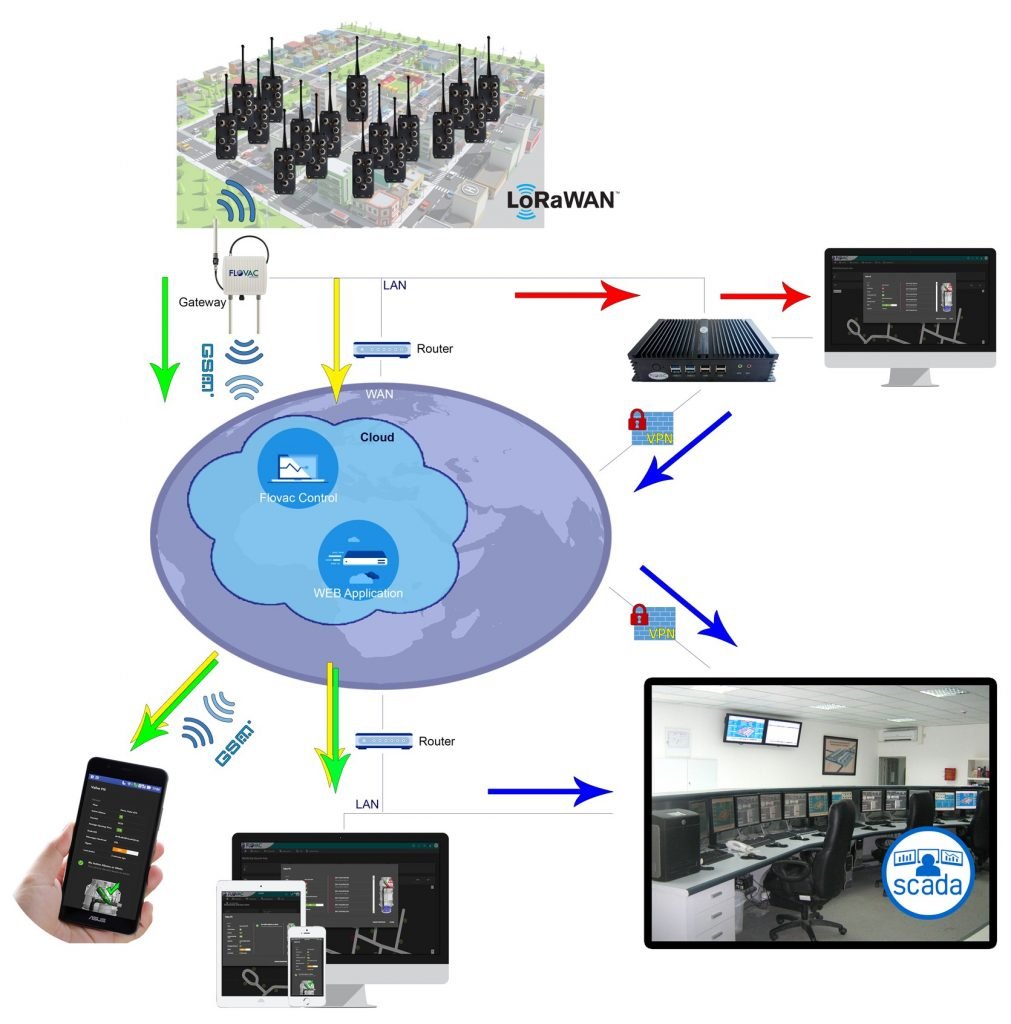

Remote Activation of Pumps

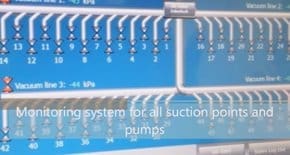

One aspect of the work that Flovac had been doing around the world was in the technology space. Flovac has pioneered the use of IOT (Internet of Things) technologies to enable remote troubleshooting of the system as well as remote operation of the system. Many existing pump out systems require the yacht manager to locate the pump station, turn it on manually (if it is working), go back to their yacht to start the operation which may take many hours to complete. If someone else is using it, or if there is a problem, it may well affect the ability of the yacht to get back into action in a timely manner. Flovac has developed an app for the phone, which the yacht owner can log into from the comfort of his or her yacht. At a glance they can see if the facility is available. Couple the yacht to the access port, push start on the phone and discharge the wastewater.

One aspect of the work that Flovac had been doing around the world was in the technology space. Flovac has pioneered the use of IOT (Internet of Things) technologies to enable remote troubleshooting of the system as well as remote operation of the system. Many existing pump out systems require the yacht manager to locate the pump station, turn it on manually (if it is working), go back to their yacht to start the operation which may take many hours to complete. If someone else is using it, or if there is a problem, it may well affect the ability of the yacht to get back into action in a timely manner. Flovac has developed an app for the phone, which the yacht owner can log into from the comfort of his or her yacht. At a glance they can see if the facility is available. Couple the yacht to the access port, push start on the phone and discharge the wastewater.

System Success

The very first yacht that tried out the new system was a new 65m superyacht, one of the larger yachts at the marina. They had experienced a lot of difficulty with the old system, often having to go to a different marina altogether as the system could not handle receiving pumped flows. With the new system, the 6,000 litre discharge took less than an hour and a “smooth operation”for all involved. Telling our operator and other boat owners that this was the best system that they had come across in Australia.

The very first yacht that tried out the new system was a new 65m superyacht, one of the larger yachts at the marina. They had experienced a lot of difficulty with the old system, often having to go to a different marina altogether as the system could not handle receiving pumped flows. With the new system, the 6,000 litre discharge took less than an hour and a “smooth operation”for all involved. Telling our operator and other boat owners that this was the best system that they had come across in Australia.

The “significant investment” that required securing the best system has now become part of the key features of the marina that gives captains the confidence that SSM can meet their requirements.

For an overview of the Sydney Superyacht Marina you can view that here

Flovac’s deployable sewerage systems have been used in a variety of projects around the world, including at the London Olympics.

Flovac’s deployable sewerage systems have been used in a variety of projects around the world, including at the London Olympics.

When design work commenced on the Reef Island project in 2008 many engineers suggested that vacuum systems could not be designed to handle flows coming from high rise buildings such as those being planned at Reef Island.

When design work commenced on the Reef Island project in 2008 many engineers suggested that vacuum systems could not be designed to handle flows coming from high rise buildings such as those being planned at Reef Island.

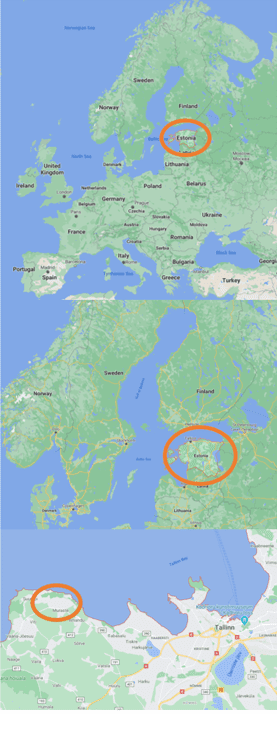

The Village of Muraste has replaced the aging septic tanks in the old part of the village which were causing environmental damage. Muraste is located 30 minutes drive north east of the capital of Estonia, Tallinn. Changing to a modern secure vacuum system will also improve the health of those in the town.

The Village of Muraste has replaced the aging septic tanks in the old part of the village which were causing environmental damage. Muraste is located 30 minutes drive north east of the capital of Estonia, Tallinn. Changing to a modern secure vacuum system will also improve the health of those in the town.

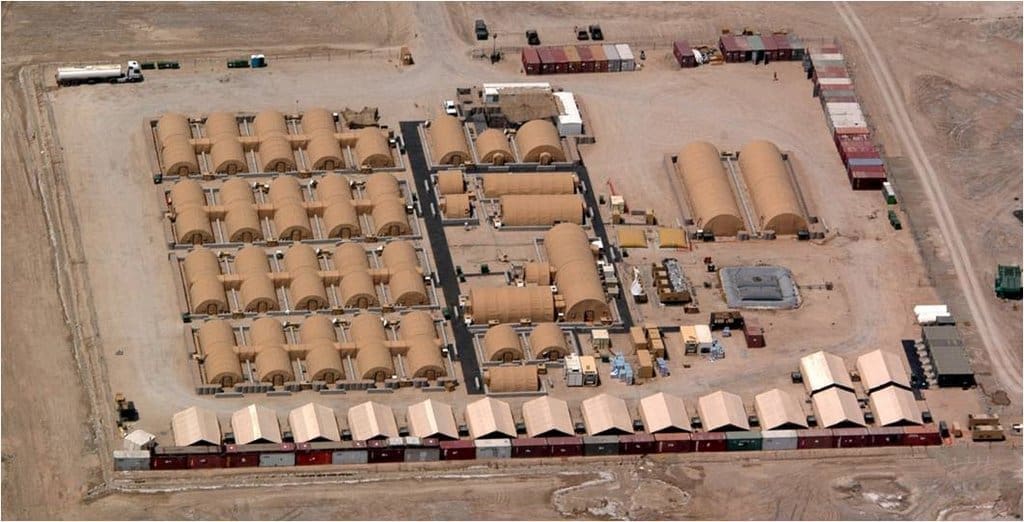

Temporary Camps, whether emergency, workers accommodation, mining, military or refugee need to transport sewage from ablution blocks, kitchens and laundries. Installation of pipework can be time consuming, expensive and be damaging to the environment.

Temporary Camps, whether emergency, workers accommodation, mining, military or refugee need to transport sewage from ablution blocks, kitchens and laundries. Installation of pipework can be time consuming, expensive and be damaging to the environment. All systems pre-tested and commissioned prior to delivery and suitable for all climates

All systems pre-tested and commissioned prior to delivery and suitable for all climates

The management team and operators at Willowbrook were particularly impressed with the speed of the evacuation of the trains as the process took a matter of seconds rather than the extensive delays that they have previously had.

The management team and operators at Willowbrook were particularly impressed with the speed of the evacuation of the trains as the process took a matter of seconds rather than the extensive delays that they have previously had. Flovac has now installed extraction systems for a number of clients in particular for the Deutsche Bahn’s ICE network, including systems in Frankfurt, Cologne and Dusseldorf.

Flovac has now installed extraction systems for a number of clients in particular for the Deutsche Bahn’s ICE network, including systems in Frankfurt, Cologne and Dusseldorf.

As we have seen with

As we have seen with