Water Supply and Sewerage in the 21st Century

The City of Marki in Poland, north east of Warsaw and Wodociag Marecki the Utility Company that maintains the water and sewerage systems in Marki City are quite unique.

There is a very close relationship between the utility, the City and Warsaw University of Technology. Over the last ten years they have done a number of concepts, designs and installations using a number of different technologies for specific sight conditions throughout their area. These have included vacuum sewers, gravity sewers, pressure systems and even domestic on-site treatment plants.

Prior to this initiative the City had relied on septic tanks so they wanted to ensure that they used the right technology for the right area and community. What has been tremendous about this effort is the city’s willingness to share their experiences with others around the country. Flovac applauds their efforts in this field and have been very happy to support them.

On a periodic basis seminars have been held to discuss their findings, the most recent of which was recently held in Zegrze near Warsaw. The seminar was titled (Water Supply and Sewerage in the 21st century) and included representatives from a number of local authorities and utilities from the north east of Poland. Experts were invited to talk on different subjects.

On Vacuum Sewerage Systems the speakers were:

Prof. Dr hab. inż. (prof. PhD Eng) Zbigniew Heidrich – Politechnika Warszawska (Warsaw Univerity of Technology)

Dr inż. (PhD Eng) Marek Kalenik – Szkoła Główna Gospodarstwa Wiejskiego (Warsaw University of Life Science)

Dr inż. (PhD Eng) Jacek Sobesto – Flovac Polska sp. z o.o.

Dr.inż. (PhD Eng) Grzegorz Stańko – Wodociąg Marecki sp. z o.o.

Dr Jacek Sobesto of Flovac Polska

One of the largest Flovac systems in Poland is based in the City of Marki and has over 800 Flovac valves connecting residents to the vacuum sewer. It has proved to be easy to maintain and well accepted by the community.

Vacuum Pump Station in Marki

Inside the Vacuum Pump Station in Marki

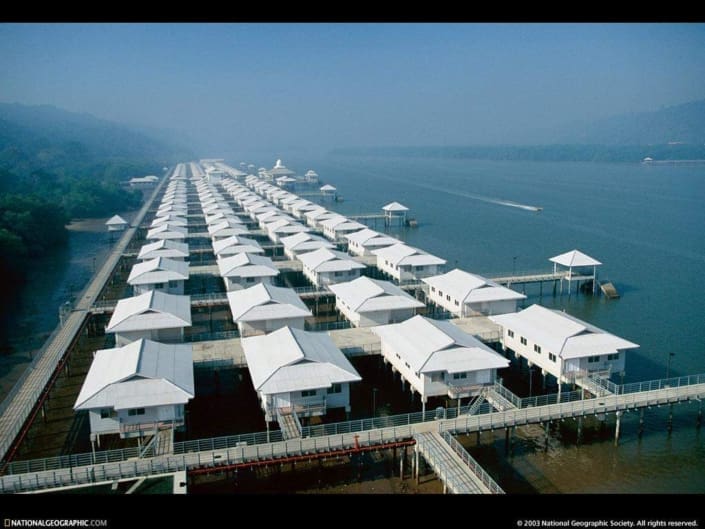

Kampong Ayer in Brunei’s capital city of Bandar Seri Begawan is a cluster of around 40 small villages connected by a 38-kilometer (23-mile) boardwalk. It dates back more than 600 years. Today, around 13,000 people live in the water village, about 3{f2ac4d1e1d40dc2e2d9280a1dfa90d854b2d8c80eba743affa37fc4ce2e16def} of the country’s population.

Kampong Ayer in Brunei’s capital city of Bandar Seri Begawan is a cluster of around 40 small villages connected by a 38-kilometer (23-mile) boardwalk. It dates back more than 600 years. Today, around 13,000 people live in the water village, about 3{f2ac4d1e1d40dc2e2d9280a1dfa90d854b2d8c80eba743affa37fc4ce2e16def} of the country’s population. Although some of the houses are now on vacuum sewer networks, many have still not been connected. Historically having raw sewerage drop into the water below only really affected the health of the local population as many of the water people swam or fished in the same water. With the wealth of those living in the villages increasing, more problems have surfaced with detergents entering the waterways, killing off the fish and other local seafood. None of this is good for tourism, especially the odour.

Although some of the houses are now on vacuum sewer networks, many have still not been connected. Historically having raw sewerage drop into the water below only really affected the health of the local population as many of the water people swam or fished in the same water. With the wealth of those living in the villages increasing, more problems have surfaced with detergents entering the waterways, killing off the fish and other local seafood. None of this is good for tourism, especially the odour. The pipework sloping to a gravity main below the houses close to the surface of the water was cut many times by local residents as it was impeding the way that many residents got around the area in their boats. For hundreds of years the residents drove their small boats under their houses and around the village. All of a sudden plastic pipes were in the way. A simple solution – cut them.

The pipework sloping to a gravity main below the houses close to the surface of the water was cut many times by local residents as it was impeding the way that many residents got around the area in their boats. For hundreds of years the residents drove their small boats under their houses and around the village. All of a sudden plastic pipes were in the way. A simple solution – cut them. As the pipework was laid directly under the walkways it was not visible and did not impact on the passage of the residents. The number one lesson for residents was to learn not to use their toilet as a rubbish bin. Initially blockages were common and operators grew frustrated by the number of items thrown into the system. The problem residents were easily found as with only 4 houses connected to a sump, the process of elimination was easy and the residents were educated as to proper use. Modern valve monitoring systems will make this even easier.

As the pipework was laid directly under the walkways it was not visible and did not impact on the passage of the residents. The number one lesson for residents was to learn not to use their toilet as a rubbish bin. Initially blockages were common and operators grew frustrated by the number of items thrown into the system. The problem residents were easily found as with only 4 houses connected to a sump, the process of elimination was easy and the residents were educated as to proper use. Modern valve monitoring systems will make this even easier.

If you are part of a coastal community it could be worse, your old broken pipes could be letting seawater into the system every time there is a high tide or major storm. Salt water can cause major problems at the Treatment Plant. For communities like Miami Beach who get storm surges flooding their sewers and closing their beach on an increasingly regular basis it can cause major economic and health risks. Santa Pola in the Alicante area of Spain found that the impact of global warming and rising sea levels caused a complete failure of their old sewer system.

If you are part of a coastal community it could be worse, your old broken pipes could be letting seawater into the system every time there is a high tide or major storm. Salt water can cause major problems at the Treatment Plant. For communities like Miami Beach who get storm surges flooding their sewers and closing their beach on an increasingly regular basis it can cause major economic and health risks. Santa Pola in the Alicante area of Spain found that the impact of global warming and rising sea levels caused a complete failure of their old sewer system. The town of Santa Pola with over 10,000 homes replaced their whole gravity sewer system with a Flovac vacuum sewerage system. As vacuum mains are laid in shallow trenches it was possible to skirt around, above and below exiting infrastructure and eventually replace the network.

The town of Santa Pola with over 10,000 homes replaced their whole gravity sewer system with a Flovac vacuum sewerage system. As vacuum mains are laid in shallow trenches it was possible to skirt around, above and below exiting infrastructure and eventually replace the network.  When looking at upgrading a gravity sewer, pipe relining can be an option, but in many cases this becomes an ongoing expensive option and be too difficult in a large network. Some utilities just look to replace the old pipework, but in most communities this is just not practical. This could mean uprooted gardens, roads out of use for a number of months, noise, dust and a huge cost.

When looking at upgrading a gravity sewer, pipe relining can be an option, but in many cases this becomes an ongoing expensive option and be too difficult in a large network. Some utilities just look to replace the old pipework, but in most communities this is just not practical. This could mean uprooted gardens, roads out of use for a number of months, noise, dust and a huge cost. Flovac vacuum sewers have shown time and again, their versatility. This means either their ability to handle density changes or climate changes. It might even mean changes in ground conditions as happened in Christchurch New Zealand when they suffered from a terrible earthquake. The old gravity sewers in the city and surrounding suburbs broke and left residents with no service for months. Vacuum sewers have now replaced a large portion of the gravity sewers in Christchurch and although difficult has proved to be a better long term solution for the residents and operators.

Flovac vacuum sewers have shown time and again, their versatility. This means either their ability to handle density changes or climate changes. It might even mean changes in ground conditions as happened in Christchurch New Zealand when they suffered from a terrible earthquake. The old gravity sewers in the city and surrounding suburbs broke and left residents with no service for months. Vacuum sewers have now replaced a large portion of the gravity sewers in Christchurch and although difficult has proved to be a better long term solution for the residents and operators.

As the project was quite remote Flovac supplied a containerized plug and play vacuum pump station and treatment plant. All water on the island is supplied by a desalination plant, so water is precious and spared as much as possible. Treatment quality is very important so that this pristine area is not polluted in any way.

As the project was quite remote Flovac supplied a containerized plug and play vacuum pump station and treatment plant. All water on the island is supplied by a desalination plant, so water is precious and spared as much as possible. Treatment quality is very important so that this pristine area is not polluted in any way.

A high profile project and one of the largest scale vacuum sewerage systems ever designed had an official opening this month in Bahrain for its key resort project.

A high profile project and one of the largest scale vacuum sewerage systems ever designed had an official opening this month in Bahrain for its key resort project.

There are space for 1200 animals on Ås farm, which consists of five buildings totaling 16,400 square meters . Small sheep (sheep and goats) have been accommodated in an airy barn of 1630 sqm, while the pigs have got their own 1740 sqm building with warmth in the floor. The entire livestock unit of 7140 sqm is equipped with two fully automatic milking robots, an advanced robot that can supply feed to the cows throughout the day.

There are space for 1200 animals on Ås farm, which consists of five buildings totaling 16,400 square meters . Small sheep (sheep and goats) have been accommodated in an airy barn of 1630 sqm, while the pigs have got their own 1740 sqm building with warmth in the floor. The entire livestock unit of 7140 sqm is equipped with two fully automatic milking robots, an advanced robot that can supply feed to the cows throughout the day. The STATSBYGG design group chose to work with Flovac after a close study of the Veterinary University of Hanover’s epidemic disease prevention unit’s use of the Flovac vacuum sewerage system installed in 2015. They cited the speed of installation, flexibility and that there had been virtually no operational issues and no contamination occurrences as the reason for choosing Flovac.

The STATSBYGG design group chose to work with Flovac after a close study of the Veterinary University of Hanover’s epidemic disease prevention unit’s use of the Flovac vacuum sewerage system installed in 2015. They cited the speed of installation, flexibility and that there had been virtually no operational issues and no contamination occurrences as the reason for choosing Flovac. A number of tests on the vacuum system were done, including a leakage test to show that if the vacuum mains were broken in anyway there would still be no blockage. A video of that test is available here if you would like to watch it.

A number of tests on the vacuum system were done, including a leakage test to show that if the vacuum mains were broken in anyway there would still be no blockage. A video of that test is available here if you would like to watch it.

neighborhood complete with a Foodstuffs supermarket, cafe’s and restaurants. Already built is a large BP service station which houses a cafe and a Jetwash. The Flovac system handles the commercial premises and can handle any flows from the car washing facility.

neighborhood complete with a Foodstuffs supermarket, cafe’s and restaurants. Already built is a large BP service station which houses a cafe and a Jetwash. The Flovac system handles the commercial premises and can handle any flows from the car washing facility.

A FLOVAC delegation was recently in Chile, in the Llay-Llay commune, where the first vacuum sewerage installation of the country is being built. As this technology is innovative for the Chilean technicians, a conference was organized for everyone interested in FLOVAC’s system, having it coincide with the formation day of the Regional Development Subsecretary (SUBDERE).

A FLOVAC delegation was recently in Chile, in the Llay-Llay commune, where the first vacuum sewerage installation of the country is being built. As this technology is innovative for the Chilean technicians, a conference was organized for everyone interested in FLOVAC’s system, having it coincide with the formation day of the Regional Development Subsecretary (SUBDERE).

For the regional manager of Subdere Valparaíso, Eduardo Pasten, the pioneering and innovative project that is implemented in Llay Llay, can be replicated in other cities of the country. He emphasizes the importance of the presence of representatives from all over Chile, “in order to be able to disseminate, and if applicable in the regions, to implement it,” Pasten said.

For the regional manager of Subdere Valparaíso, Eduardo Pasten, the pioneering and innovative project that is implemented in Llay Llay, can be replicated in other cities of the country. He emphasizes the importance of the presence of representatives from all over Chile, “in order to be able to disseminate, and if applicable in the regions, to implement it,” Pasten said. Another important consideration was the low amount of power that is required for the vacuum pump station. With power required only at the vacuum pump station a back up generator can easily be supplied if there is any interruption to local power supplies.

Another important consideration was the low amount of power that is required for the vacuum pump station. With power required only at the vacuum pump station a back up generator can easily be supplied if there is any interruption to local power supplies.

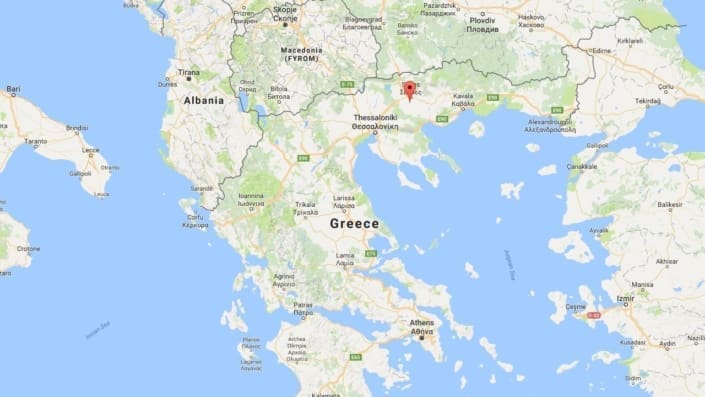

Flovac Greece has just completed the largest vacuum sewerage system ever undertaken in Greece covering the towns of Mitrousi and Skoutari in the Serres Region of northern Greece.

Flovac Greece has just completed the largest vacuum sewerage system ever undertaken in Greece covering the towns of Mitrousi and Skoutari in the Serres Region of northern Greece. The Serres region is an environmentally important area which won a European sustainable tourism award for aquatourism. A large artificial lake, Lake Kerkini was created nearby to make use of the extensive marshlands in the area. This is also behind the need for vacuum sewers in the villages as the water table is very high and actually visible on the surface in some areas.

The Serres region is an environmentally important area which won a European sustainable tourism award for aquatourism. A large artificial lake, Lake Kerkini was created nearby to make use of the extensive marshlands in the area. This is also behind the need for vacuum sewers in the villages as the water table is very high and actually visible on the surface in some areas.